Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By hqt

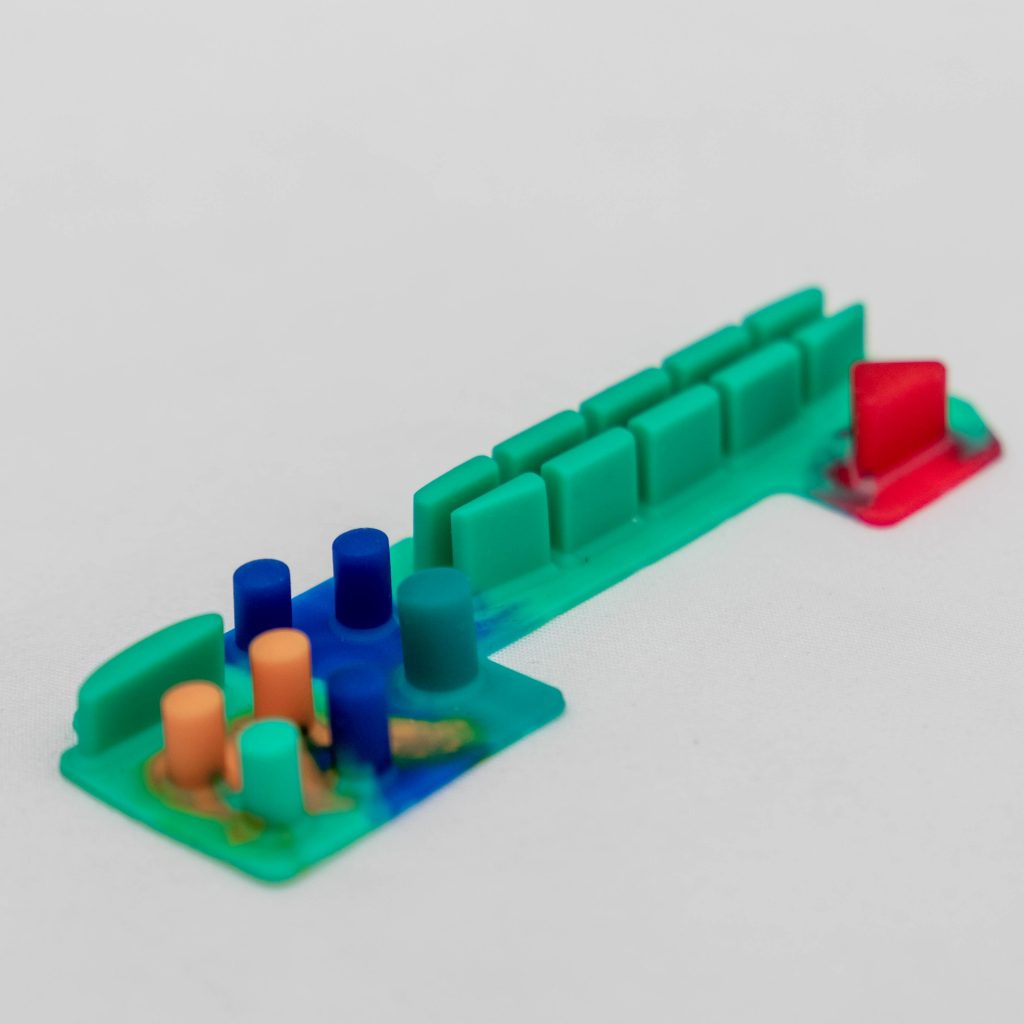

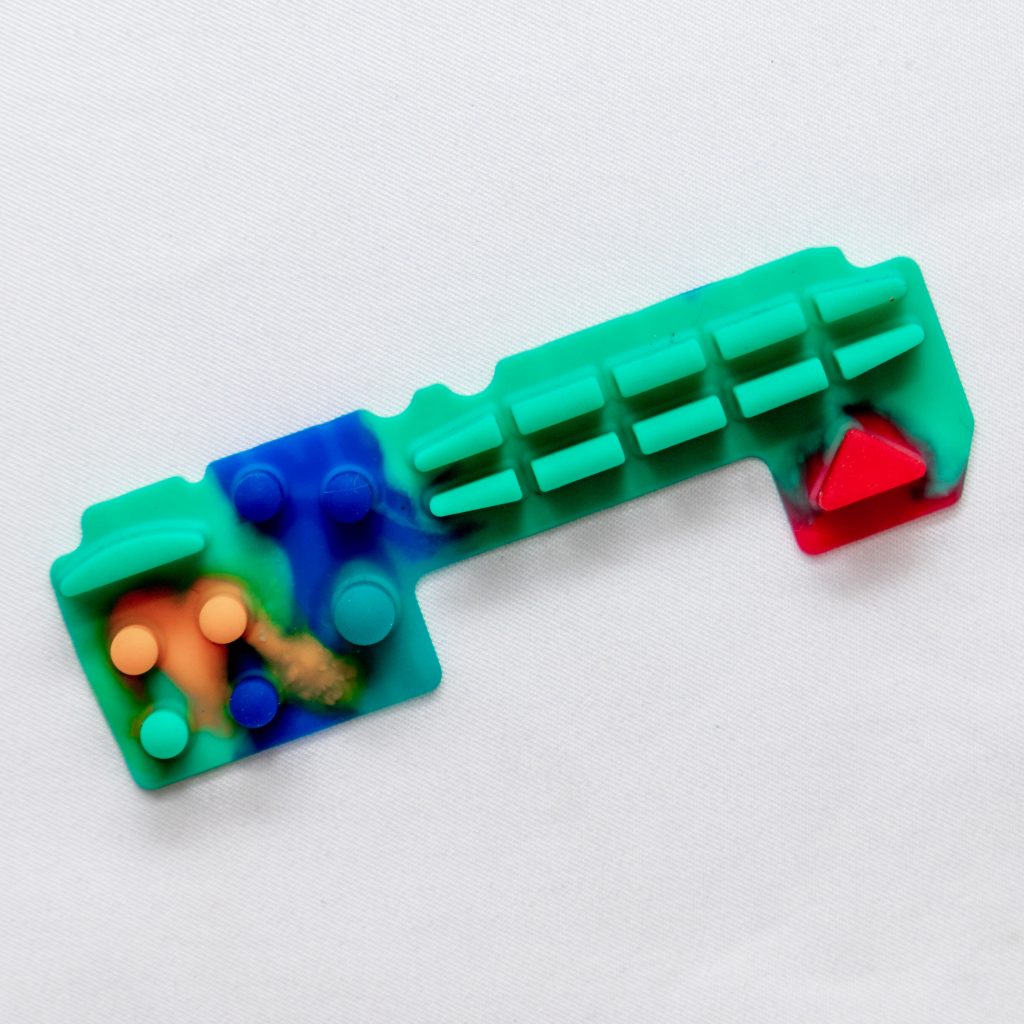

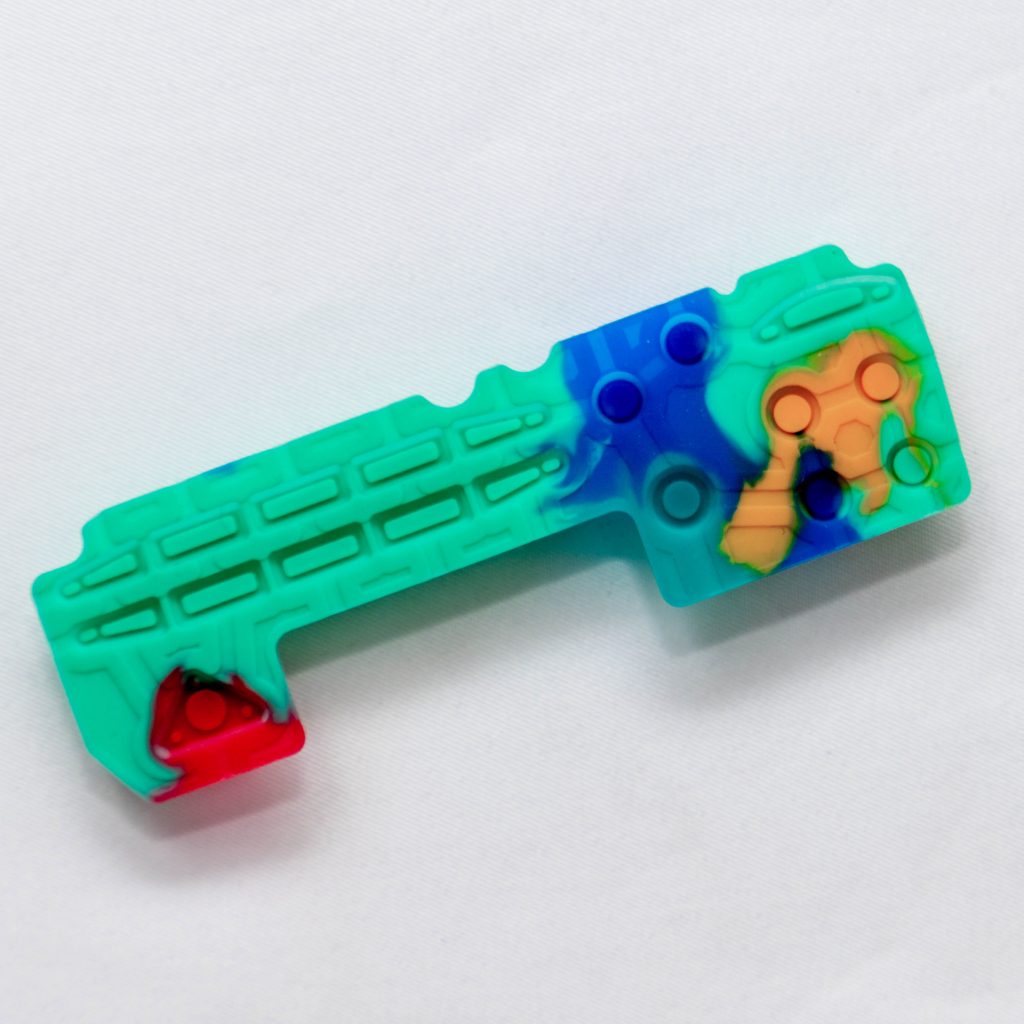

Silicone Rubber Keypadshave become a popular choice for electronic device manufacturers due to their durability, flexibility, and resistance to extreme temperatures. In the manufacturing process of silicone rubber keypads, printing plays a crucial role in ensuring that the final product is functional and aesthetically appealing. In this article, we will explore the various options for printing Silicone Rubber Keypads.

There are four main options for printing Silicone Rubber Keypads: Screen Printing, Pad Printing, Laser Etching, and Digital Printing.

A. Screen Printing:

Screen printing is the most commonly used method for printing Silicone Rubber Keypads. It involves transferring ink through a stencil onto the keypad surface. Screen printing allows for high-quality printing with bold and vivid colors, making it suitable for complex designs. However, it is not the most durable option for printing, as the ink may peel off over time.

B. Pad Printing:

Pad printing involves transferring ink from a pad to the Silicone Rubber Keypad surface. This method is more durable than screen printing, as it can withstand abrasion and exposure to harsh environments. Pad printing is also capable of printing fine details and intricate designs.

C. Laser Etching:

Laser Etching involves using a laser beam to burn the surface of the Silicone Rubber Keypad to create an impression. This method is highly durable and can produce precise and intricate designs. However, it is not suitable for printing colors and shades, as it only creates a single color.

D. Digital Printing:

Digital Printing involves using a printer to transfer the ink directly onto the Silicone Rubber Keypad surface. This method produces high-quality prints with vibrant colors, making it ideal for complex designs with multiple colors and shades. Digital printing is also highly efficient and cost-effective for small batches of keypads.

When it comes to choosing a printing option for Silicone Rubber Keypads, several factors need to be considered, including printing quality, durability, cost-effectiveness, and time efficiency.

A. Printing Quality:

Screen printing and digital printing produce high-quality prints with vibrant colors and fine details. Pad printing and laser etching, on the other hand, produce precise and intricate designs but may lack in color vibrancy.

B. Durability:

Pad printing and laser etching are the most durable printing options, as they can withstand harsh environments and abrasion. Screen printing may peel off over time, while digital printing may fade or scratch.

C. Cost-effectiveness:

Screen printing and pad printing are the most cost-effective options for printing large batches of Silicone Rubber Keypads. Laser etching and digital printing are more expensive, especially for small batches.

D. Time Efficiency:

Digital printing is the most time-efficient option,as it allows for quick and easy printing without the need for setup and cleanup. Screen printing and pad printing may take longer, as they require setup time and cleaning between batches. Laser etching may take the longest, as it involves a precise and intricate process.

Several factors need to be considered when choosing a printing option for Silicone Rubber Keypads.

A. Design Complexity:

Screen printing and digital printing are suitable for complex designs with multiple colors and shades. Pad printing and laser etching are more suitable for intricate designs with fine details.

B. Colors and Shades:

Screen printing and digital printing are capable of printing multiple colors and shades, while pad printing and laser etching are limited to a single color.

C. Material Properties:

The material properties of Silicone Rubber Keypads may affect the choice of printing option. Screen printing and pad printing are suitable for most materials, while laser etching may not be suitable for all materials.

D. Quantity of Keypads to be Printed:

The quantity of Silicone Rubber Keypads to be printed may also affect the choice of printing option. Screen printing and pad printing are more cost-effective for large batches, while digital printing may be more cost-effective for small batches.

Printing is a crucial step in the manufacturing process of Silicone Rubber Keypads. The choice of printing option depends on several factors, including printing quality, durability, cost-effectiveness, time efficiency, design complexity, colors and shades, material properties, and quantity of keypads to be printed. Manufacturers should carefully consider these factors when choosing a printing option to ensure that the final product is functional and aesthetically appealing.

FAQs:

What is Silicone Rubber Keypad printing

Do you have any questions, or would you like to speak directly with a representative?