Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By hqt

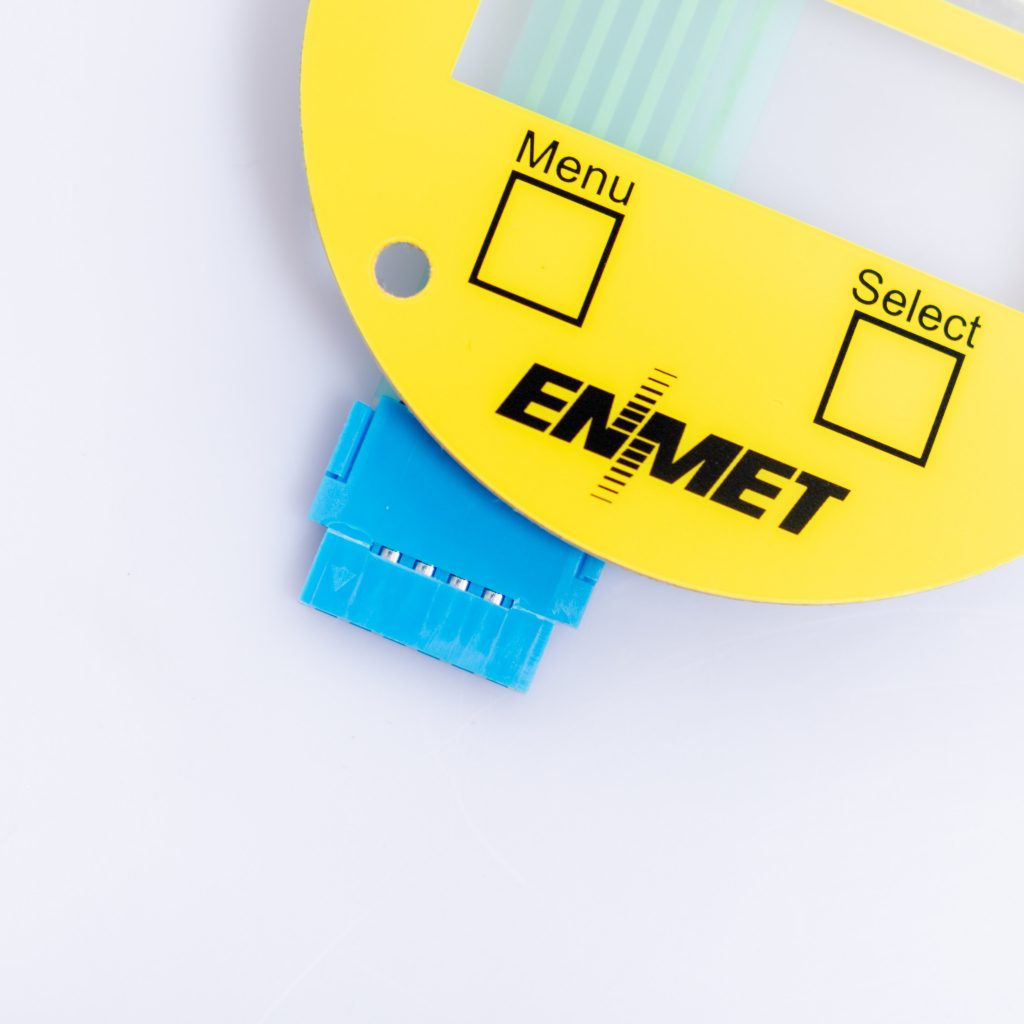

Membrane switches are widely used in various industries for their versatility and durability. They provide a cost-effective solution for user interface applications, offering a compact design and customizable options. One important aspect of membrane switches is the connector that enables the interface between the switch and the circuit. In this article, we will explore the connector options available for membrane switches, discussing their pros and cons.

Connectors play a crucial role in the functionality and performance of membrane switches. They establish electrical connections between the switch and the circuit, allowing the transmission of signals. Let’s dive into the various connector options and understand their pros and cons.

Flexible Printed Circuits (FPCs) are a common connector option for membrane switches. They are thin, lightweight, and flexible, making them suitable for applications with limited space. FPCs offer excellent signal transmission capabilities and can withstand repeated flexing without compromising performance. Their flexible nature allows for easy integration into complex designs.

Pros:

Cons:

Zero Insertion Force (ZIF) connectors are widely used in membrane switches due to their easy installation process. These connectors feature a low insertion force mechanism, allowing for quick and hassle-free connection. ZIF connectors provide good electrical performance and are available in various sizes and configurations to accommodate different switch designs.

Pros:

Cons:

Printed Circuit Board (PCB) edge connectors are another option for connecting membrane switches. These connectors are attached to the edge of the PCB and provide a reliable electrical connection. PCB edge connectors offer good mechanical stability and can handle higher currents compared to some other options.

Pros:

Cons:

Wire harnesses involve the use of wires and connectors to establish the connection between the membrane switch and the circuit. They provide flexibility and ease of customization, allowing for different configurations based on the application requirements. Wire harnesses are commonly used in situations where the switch and the circuit are physically separated.

Pros:

Cons:

Snap connectors, also known as quick-connect terminals, are a simple and cost-effective option for membrane switches. These connectors feature a male-female snap mechanism, allowing for easy and secure connections. Snap connectors are widely used in applications where frequent disconnection and reconnection are required.

Pros:

Cons:

Flat Flexible Cable (FFC) and Flexible Printed Circuit (FPC) connectors are often used in membrane switches that require high-density connections. These connectors consist of a flat cable with conductive traces and contacts for connection. FFC/FPC connectors offer excellent signal transmission and can handle high data rates.

Pros:

Cons:

1. Are membrane switches compatible with multiple connector options?

Yes, membrane switches can be designed to be compatible with various connector options. The choice of connector depends on the specific requirements of the application, including space limitations, electrical performance, and ease of installation.

2. Can I change the connector type for an existing membrane switch design?

In most cases, it is possible to change the connector type for an existing membrane switch design. However, it may require modifications to the switch design and careful consideration of factors such as compatibility, space requirements, and electrical performance.

3. Which connector option is the most cost-effective?

The cost-effectiveness of a connector option depends on various factors, including the specific requirements of the application, production volume, and desired performance. Generally, snap connectors and wire harnesses are considered more cost-effective options compared to FPCs or FFCs.

4. What are the factors to consider when choosing a connector for a membrane switch?

When choosing a connector for a membrane switch, some key factors to consider include electrical performance, mechanical stability, space limitations, durability, installation process, and cost.

5. Can connectors be customized for specific application requirements?

Yes, connectors can be customized to meet specific application requirements. Customization options may include different pin configurations, sizes, materials, and additional features such as shielding or locking mechanisms.

6. Can I combine different connector options in a single membrane switch design?

Yes, it is possible to combine different connector options in a single membrane switch design. This approach allows for flexibility in addressing different connection needs within the same switch assembly.

Choosing the right connector option for a membrane switch is crucial to ensure optimal performance and reliability. Each connector option has its own set of pros and cons, depending on the specific requirements of the application. By understanding the characteristics of each connector type and considering factors such as space limitations, electrical performance, and cost, you can make an informed decision that meets your needs. Whether it’s FPCs, ZIF connectors, PCB edge connectors, wire harnesses, snap connectors, or FFC/FPC connectors, each option offers unique advantages that can be tailored to your specific application.

Do you have any questions, or would you like to speak directly with a representative?