Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By hqt

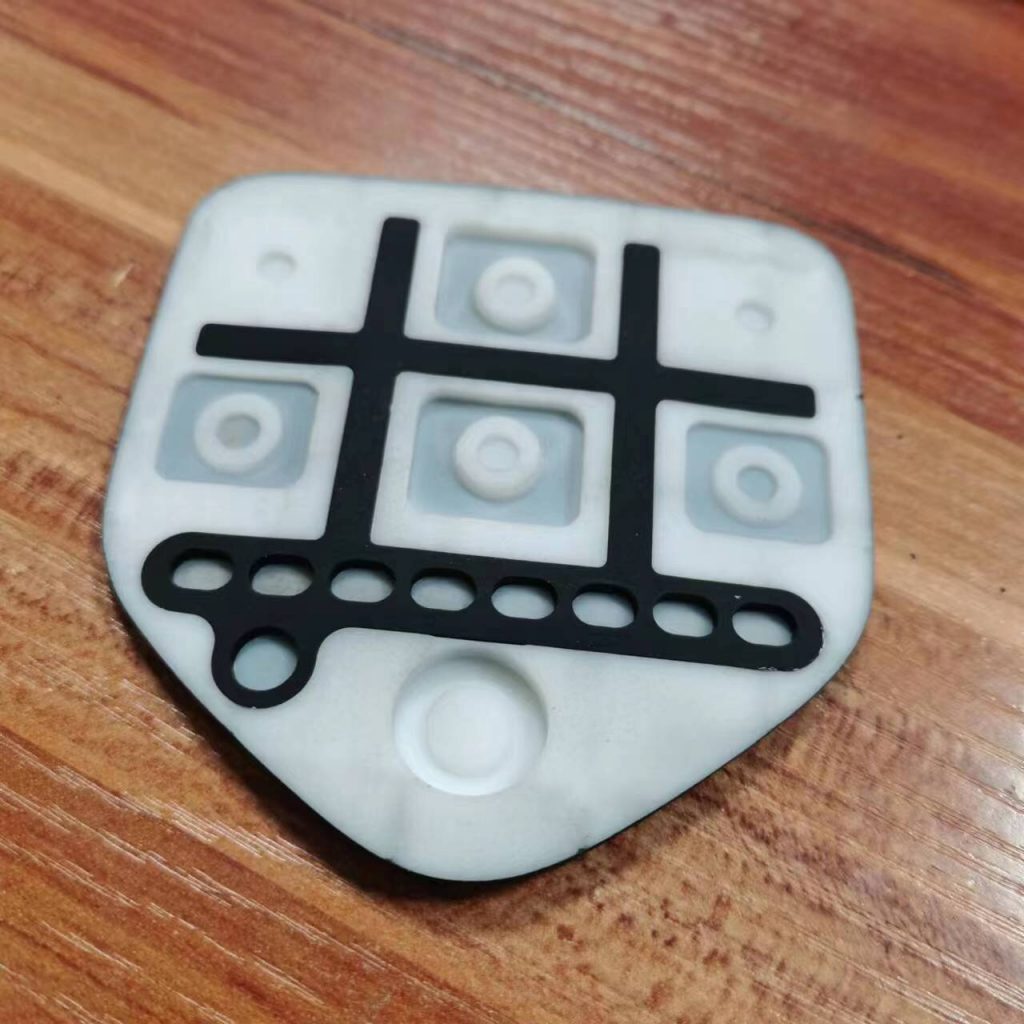

Silicone rubber keypads are widely used in various industries because of their flexibility, durability, and ease of use. Backlighting is an essential feature that enhances the visual appeal and user experience of silicone rubber keypads. There are several options available for backlighting silicone rubber keypads, and this article will explore them in detail.

There are several options available for backlighting silicone rubber keypads, including laser etching, light guide film, printed film backlighting, and dual shot molding. Each of these options has its advantages and disadvantages, and the choice depends on the specific requirements of the application.

Laser etching

Laser etching is a process that involves using a laser to engrave a pattern or design on the silicone rubber keypad. The laser removes a thin layer of the silicone rubber to create a recessed area that allows light to shine through. The recessed area can be filled with a translucent material that diffuses the light and creates a backlight effect.

The benefits of laser etching include high precision, sharp edges, and the ability to create intricate designs. Laser etching is also durable and resistant to wear and tear, making it ideal for applications that require frequent use.

Light guide film

Light guide film is a thin, flexible sheet that is placed underneath the silicone rubber keypad. The film is designed to distribute the light evenly across the keypad, creating a uniform backlight effect. The film can be customized to match the specific size and shape of the keypad.

The benefits of light guide film include uniform illumination, low power consumption, and ease of installation. Light guide film is also highly customizable, making it ideal for applications that require unique shapes or designs.

Printed film backlighting

Printed film backlighting is a process that involves printing a design or pattern on a translucent film that is then placed underneath the silicone rubber keypad. The film allows light to shine through the printed areas, creating a backlight effect.

The benefits of printed film backlighting include high customization, low cost, and ease of installation. Printed film backlighting is also durable and resistant to wear and tear, making it ideal for applications that require frequent use.

Dual shot molding

Dual shot molding is a process that involves injecting two different materials into a mold to create a single part. The first material is used to create the base of the keypad, while the second material is used to create a translucent or transparent layer on top of the base.

The benefits of dual shot molding include high durability, long lifespan, and the ability to create complex designs. Dual shot molding is also highly customizable, making it ideal for applications that require unique shapes or designs.

Backlighting silicone rubber keypads can be used in a variety of applications, including medical devices, industrial equipment, and consumer electronics. In medical devices, backlighting can enhance the visibility of key functions and improve patient safety. In industrial equipment, backlighting can improve worker productivity and reduce errors. In consumer electronics, backlighting can enhance the visual appeal and user experience of the product

In conclusion, there are several options available for backlighting silicone rubber keypads, each with its own advantages and disadvantages. Laser etching offers high precision and durability, light guide film provides uniform illumination and ease of installation, printed film backlighting is highly customizable and low cost, and dual shot molding offers complex designs and high durability. The choice of backlighting option depends on the specific requirements of the application.

Q1. Can any silicone rubber keypad be backlit?

A: Yes, most silicone rubber keypads can be backlit using one of the available backlighting options.

Q2. Are there any limitations to the designs that can be created with backlighting?

A: There may be some limitations depending on the chosen backlighting option, but in general, intricate designs and patterns can be created with all options.

Q3. How long does the backlighting last?

A: The lifespan of the backlighting depends on the chosen option and the specific conditions of use. However, all options are designed to be durable and long-lasting.

Q4. Is backlighting expensive?

A: The cost of backlighting depends on the chosen option, the size and complexity of the keypad, and the volume of production. However, all options are generally affordable and cost-effective.

Q5. Can backlighting be customized to match specific brand colors?

A: Yes, most backlighting options can be customized to match specific brand colors or other design requirements.

Do you have any questions, or would you like to speak directly with a representative?