Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By hqt

Silicone rubber keypads are a popular choice for electronic devices and appliances due to their durability, flexibility, and resistance to wear and tear. These keypads are used in a wide range of applications, including remote controls, medical equipment, and industrial machinery. The color of the silicone rubber keypad plays an important role in its functionality and appearance, and there are different methods used to achieve the desired color. In this article, we will explore how the color of silicone rubber keypads is done, whether through printing or other methods.

Silicone rubber keypads are an essential component of electronic devices and appliances. They are used to control the functions of these devices, and their functionality and appearance are critical to the user experience. One important aspect of the appearance of silicone rubber keypads is their color. The color of the keypad can indicate the function of the key or provide an aesthetic appeal to the device.

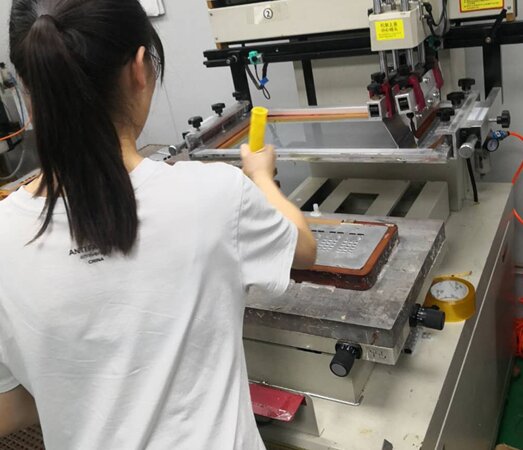

Printing is one of the most common methods used to add color to silicone rubber keypads. It involves the application of ink or paint onto the surface of the keypad using a printing technique. Printing can be done using different methods, such as screen printing, pad printing, or digital printing. Screen printing is the most popular method of printing silicone rubber keypads, and it involves creating a stencil of the design and then using a squeegee to press ink through the stencil onto the keypad.

Advantages of Printing

Printing has several advantages when it comes to adding color to silicone rubber keypads. Firstly, it allows for a wide range of colors to be used, including Pantone colors. This means that the keypad can be matched to the branding or aesthetic requirements of the device. Secondly, printing can be used to create complex designs and graphics, which can be important for devices that require a high degree of functionality. Lastly, printing is a cost-effective method of coloring silicone rubber keypads, particularly for small production runs.

Disadvantages of Printing

Printing also has some disadvantages when it comes to coloring silicone rubber keypads. Firstly, the ink or paint used in the printing process can wear off over time, particularly if the keypad is exposed to harsh environmental conditions. Secondly, printing is limited to the surface of the keypad, and the ink or paint cannot penetrate the silicone rubber material. This means that the color may not be as vibrant as desired or may not be visible if the keypad is backlit. Lastly, printing can be time-consuming, particularly for complex designs, and may require several layers of ink or paint to achieve the desired effect.

Other Methods

There are other methods used to add color to silicone rubber keypads besides printing. One such method is injection molding, which involves adding pigments or dyes to the silicone rubber material before it is molded into the keypad shape. This method is more expensive than printing, but it allows for the color to be embedded throughout the material, making it more resistant to wear and tear. Another method is laser etching, which involves using a laser to remove the surface layer of the keypad to reveal a contrasting color underneath.

The color of silicone rubber keypads is an important aspect of their functionality and appearance. Printing is the

most common method used to add color to silicone rubber keypads, but there are other methods available, such as injection molding and laser etching. Each method has its advantages and disadvantages, and the choice of method will depend on the specific requirements of the device or appliance.

Can I use any color for my silicone rubber keypad?

Yes, printing allows for a wide range of colors to be used, including Pantone colors, which can be matched to the branding or aesthetic requirements of the device.

Will the color wear off over time?

Printing can wear off over time, particularly if the keypad is exposed to harsh environmental conditions. Injection molding and laser etching are more resistant to wear and tear.

Can printing be used to create complex designs and graphics?

Yes, printing is a versatile method that can be used to create complex designs and graphics on silicone rubber keypads.

Is injection molding more expensive than printing?

Yes, injection molding is generally more expensive than printing, but it allows for the color to be embedded throughout the material, making it more resistant to wear and tear.

Can laser etching be used to add color to silicone rubber keypads?

No, laser etching involves removing the surface layer of the keypad to reveal a contrasting color underneath, but it cannot be used to add color to the keypad.

Do you have any questions, or would you like to speak directly with a representative?