Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By peter

If you’re looking for a way to create a user-friendly interface for your electronic device, you may want to consider using a PCB membrane switch. These switches are thin, flexible, and easy to use, making them an ideal choice for a variety of applications. Whether you’re designing a new product or upgrading an existing one, a PCB membrane switch can help you create a more intuitive and efficient interface for your users.

At their most basic level, PCB membrane switches are simple circuits that use pressure to open and close a circuit. They consist of several layers of materials, including a flexible membrane layer that contains conductive traces and a graphic overlay layer that displays the switch’s function and design. When a user presses on the overlay, the membrane layer flexes and makes contact with the conductive traces, completing the circuit and activating the switch.

If you’re interested in using a PCB membrane switch for your project, there are several key design considerations to keep in mind. You’ll need to choose the right materials, decide on the switch’s layout and function, and ensure that the switch is easy to use and maintain. With the right design and manufacturing process, however, you can create a high-quality switch that meets all of your requirements and exceeds your users’ expectations.

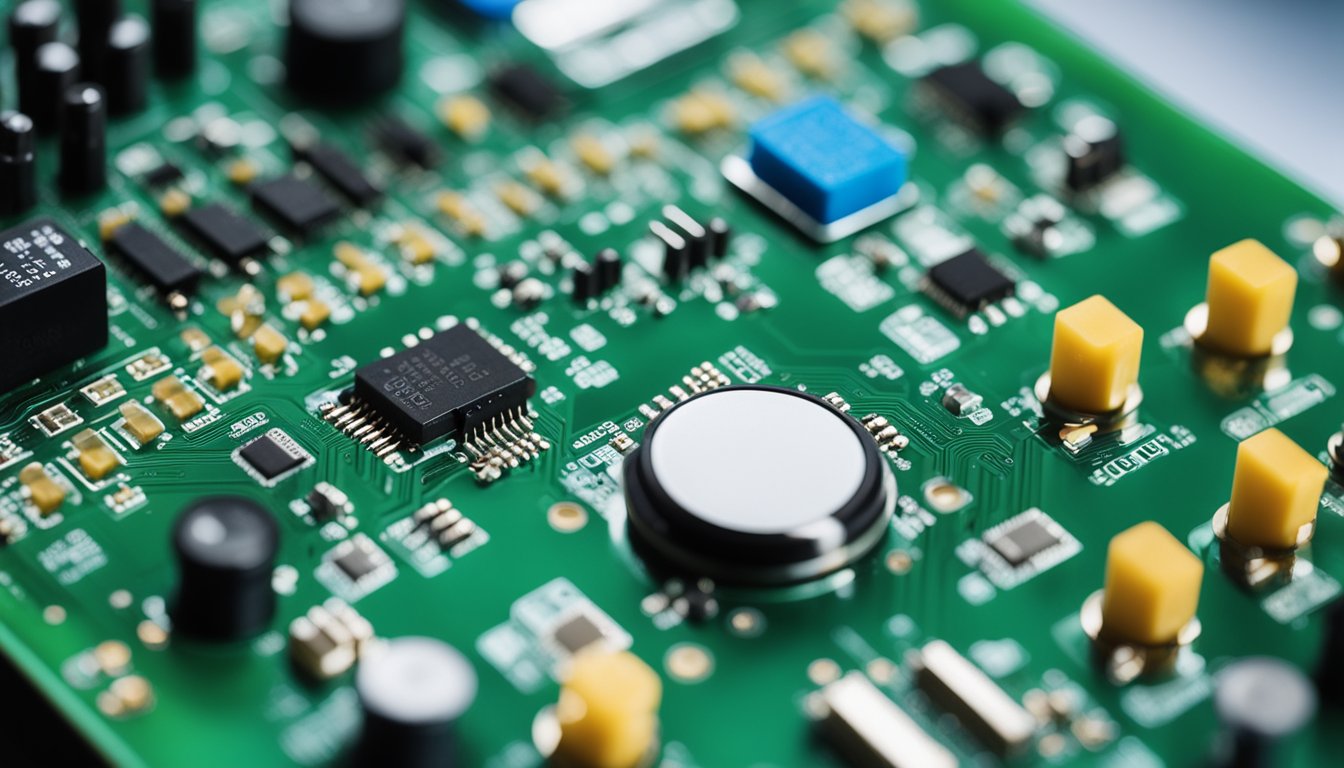

PCB membrane switches are a type of interface that allow users to communicate with electronic devices. They are made up of three layers: a top graphic overlay layer, a middle spacer layer, and a bottom circuit layer. The graphic overlay layer is the top layer of the switch, and it is where the user interacts with the switch. This layer can be customized to display graphics, text, or symbols. The middle spacer layer separates the graphic overlay layer from the bottom circuit layer. It is typically made of a flexible material, such as polyester, and has holes that line up with the circuit layer. The bottom circuit layer is where the electrical circuitry is located. It is typically made of copper and is etched to create the desired circuit pattern.

When pressure is applied to the top layer of the switch, it activates the circuit layer beneath it, completing an electrical circuit and triggering a response from the device. PCB membrane switches can be designed to be either tactile or non-tactile. Tactile switches have a physical response when they are pressed, such as a click or a snap. Non-tactile switches do not have a physical response, but instead rely on a visual or auditory signal to indicate that the switch has been activated. PCB membrane switches can also be designed to be either momentary or latching. Momentary switches only remain activated for as long as they are being pressed, while latching switches remain activated until they are pressed again.

Overall, PCB membrane switches are a reliable and cost-effective way to provide user input to electronic devices. They are used in a wide range of applications, including consumer electronics, medical equipment, and industrial controls.

Designing a PCB membrane switch requires careful consideration of various factors to ensure optimal performance and user experience. In this section, we will discuss the three main design considerations: material selection, electrical layout, and tactile feedback.

The choice of materials used in the construction of a PCB membrane switch can significantly impact its performance and durability. When selecting materials, it is essential to consider factors such as the operating environment, expected lifespan, and required actuation force.

The overlay is the top layer of the membrane switch and is the interface between the user and the switch. It is crucial to select a material that is durable, easy to clean, and comfortable to touch. Common overlay materials include polycarbonate, polyester, and acrylic.

The adhesive layer is responsible for bonding the layers of the membrane switch together. It is crucial to select an adhesive that is strong enough to hold the layers together, yet flexible enough to allow for actuation. Common adhesive materials include acrylic and silicone.

The electrical layout of a PCB membrane switch is critical to its performance. When designing the electrical layout, it is essential to consider factors such as the number of circuits, trace routing, and termination options.

Trace routing is the process of designing the conductive pathways that connect the switch to the circuit board. It is essential to ensure that the traces are wide enough to minimize resistance and carry sufficient current. Additionally, designing the traces with smooth, rounded corners can reduce stress and prevent cracking.

Termination options refer to the methods used to connect the membrane switch to the circuit board. Common termination options include ZIF connectors, solder pads, and tail terminations. When selecting a termination option, it is essential to consider factors such as ease of assembly, durability, and cost.

Tactile feedback is the physical response that a user feels when they press a switch. It is crucial to design a membrane switch with the appropriate level of tactile feedback to provide a satisfying user experience. When designing the tactile feedback, it is essential to consider factors such as actuation force, snap ratio, and key travel.

Actuation force refers to the amount of force required to activate a switch. It is essential to select an actuation force that is comfortable for the user and provides the desired level of tactile feedback.

Snap ratio refers to the ratio of the force required to activate a switch to the force required to hold the switch closed. A higher snap ratio can provide a more satisfying tactile feedback.

Key travel refers to the distance that a key travels when it is pressed. It is essential to select a key travel that is comfortable for the user and provides the desired level of tactile feedback.

In conclusion, designing a PCB membrane switch requires careful consideration of various factors to ensure optimal performance and user experience. By selecting the appropriate materials, designing the electrical layout correctly, and designing the tactile feedback, you can create a membrane switch that provides a satisfying user experience.

PCB membrane switches are widely used in the electronics industry due to their durability, reliability, and versatility. The manufacturing process of PCB membrane switches involves several critical steps, including printing, cutting, and assembly. In this section, we will delve into the intricate process of manufacturing PCB membrane switches and uncover the technology and techniques that bring them to life.

The first step in the manufacturing process of PCB membrane switches is printing and cutting. The printing process involves printing the circuit pattern on a polyester film using conductive ink. The circuit pattern is designed using computer-aided design (CAD) software and then printed onto the polyester film. The conductive ink is made of silver, carbon, or copper, and it allows the switch to conduct electricity. After printing, the polyester film is laminated with a protective layer to prevent damage.

The cutting process involves cutting the printed polyester film into the desired shape and size using a die-cutting machine. The die-cutting machine uses a sharp metal die to cut the polyester film into the desired shape. The die-cutting process is precise and accurate, ensuring that each switch is identical.

The second step in the manufacturing process of PCB membrane switches is assembly. The assembly process involves bonding the printed and cut polyester film to a printed circuit board (PCB) using pressure-sensitive adhesive. The PCB provides support for the switch and allows it to be connected to other electronic components. The pressure-sensitive adhesive is applied to the back of the polyester film, and the film is then carefully aligned and bonded to the PCB.

After bonding, the switch is tested for functionality and durability. The switch is tested for its ability to conduct electricity, its resistance to wear and tear, and its ability to withstand environmental factors such as temperature and humidity. Once the switch passes all the tests, it is ready to be used in electronic devices.

In conclusion, the manufacturing process of PCB membrane switches is a precise and intricate process that requires advanced technology and techniques. The printing and cutting process involves printing the circuit pattern on a polyester film using conductive ink and cutting the film into the desired shape and size using a die-cutting machine. The assembly process involves bonding the printed and cut polyester film to a printed circuit board using pressure-sensitive adhesive and testing the switch for functionality and durability.

PCB membrane switches are widely used in various electronic devices and control panels. These switches are popular because of their durability, flexibility, and cost-effectiveness. Here are some of the applications and uses of PCB membrane switches:

PCB membrane switches are commonly used in consumer electronics, such as remote controls, calculators, and digital cameras. These switches are perfect for applications where a low profile, lightweight, and compact design is required. They are also ideal for applications where feedback is critical for user reassurance. Tactile switches are designed to provide tactile feedback to the user, which makes them perfect for consumer electronics.

PCB membrane switches are also used in industrial controls, such as machinery, equipment, and instruments. These switches are perfect for applications where a high level of durability, reliability, and resistance to harsh environmental conditions is required. They are also ideal for applications where the switch needs to be sealed against dust, moisture, and other contaminants. PCB membrane switches can be designed to withstand extreme temperatures, vibrations, and exposure to saltwater.

In summary, PCB membrane switches are versatile and can be used in a wide range of applications. They are popular because of their durability, flexibility, and cost-effectiveness. Whether you need a switch for a consumer electronics device or an industrial control panel, PCB membrane switches are an excellent choice.

To ensure that your PCB membrane switch lasts for a long time, it’s important to perform regular maintenance and troubleshoot any issues that arise. Here are some tips to help you keep your switch in top condition:

The first step in maintaining your PCB membrane switch is to keep it clean. Dirt, dust, and other debris can accumulate on the surface of the switch, which can interfere with its performance. To clean your switch, simply wipe it down with a soft, dry cloth. If there are stubborn stains or grime on the surface, you can use a mild detergent solution to clean the switch. Be sure to use a soft cloth or sponge to avoid scratching the surface of the switch.

If you notice that your PCB membrane switch is not functioning properly, there are a few things you can do to troubleshoot the issue. Here are some common problems and their solutions:

If you have tried troubleshooting your PCB membrane switch and it still isn’t functioning properly, you may need to replace it. Replacement switches are readily available and easy to install. Be sure to purchase a switch that is compatible with your device and follow the manufacturer’s instructions for installation.

By performing regular maintenance and troubleshooting any issues that arise, you can ensure that your PCB membrane switch functions properly for a long time.

Do you have any questions, or would you like to speak directly with a representative?