Understand the needs of customers, let customers understand the impact of materials and design on products, customize high value-added (increasing market competitiveness) options, and formulate suitable customer plans to improve the design drawings for customers to confirm, produce, and QC detects the packaging.

Understand the needs of customers:

Niceone-Keypad’s team will understand the customer’s product application direction and budget expenditure, and give the customer the most suitable product draft design. The design and material selection of Medical equipment are far from the design and material selection of marine equipment. In order to facilitate the understanding of customers, Niceone-Keypad has made a document on the influence of materials and design choices on the product.

Material aspect:

How is Membrane Switch completely designed? First understand the customer’s products and needs:

The customer’s Membraen Switch application environment and needs are placed first because it determines the product design and price factors.

Application environment-choice of materials

*Application environment of Membrane Switch:

Temperature: Temperature has the greatest impact on the use of Membrane Switch is adhesive.

10 to 60 degrees Celsius can choose DT adhesive made in China or Nitto adhesive made in Japan. This type can satisfy.

-20 to 100 degrees Celsius requires 3M Adhesive.

*Indoor: indoor problems are mainly anti-glare problems and avoid key operation errors.

Overlay chooses F or V series frosted Polyester material made by Autotex (this kind of material is not reflective), or EB series glare material but printed with anti-glare coating. Polycarbonate is also a good choice.

*Outdoor: The problem of outdoor is mainly long-term ultraviolet radiation and waterproof problems.

UV:

Overlay needs to choose HP92W, UV-resistant Silicone Rubber Keypad or Kotutai’s XE material as the material of Membrane Switch.

Waterproof problem:

Choose Adhesive or Overlay with strong adhesion and choose Silicone Rubber Keypad as the waterproof panel. In terms of structure, you can choose a waterproof frame structure or a structure surrounded by silica gel.

*Medical environment: There are many bacteria and corrosive liquids in the medical environment, and the buttons need to respond in a timely manner.

The panel material is best to choose antibacterial AM series Kotutai or antibacterial Silicone Rubber Keypad. For sensitive response, you need to choose Flex copper circuit or PCB as the circuit. Even some PET line head-wearing silver needs to use silver chloride to avoid allergies.

*Military environment: harsh external environment and even high-vibration environment appear from time to time.

The materials can be selected from well-known brands of Kotutai and 3M adhesive tape. The high vibration proves that the original electronic parts of the product need to be able to withstand high-intensity frequency vibration, and all kinds of electronic parts that require PCB and FPC as the circuit to weld all kinds of electronic parts can pass this kind of problem.

*Kitchen environment: oil pollution and high temperature need to be considered.

Choosing 3M Adhesive and regular Polyester can fully meet the design requirements.

*Nautical environment: Mainly caused by long-term ultraviolet radiation and waterproof problems.

UV:

Overlay needs to choose HP92W, UV-resistant Silicone Rubber Keypad or Kotutai’s XE material as the material of Membrane Switch.

Waterproof problem:

Choose Adhesive or Overlay with strong adhesion and choose Silicone Rubber Keypad as the waterproof panel. In terms of structure, you can choose a waterproof frame structure or a structure surrounded by silica gel.

Selection of electronic accessories:

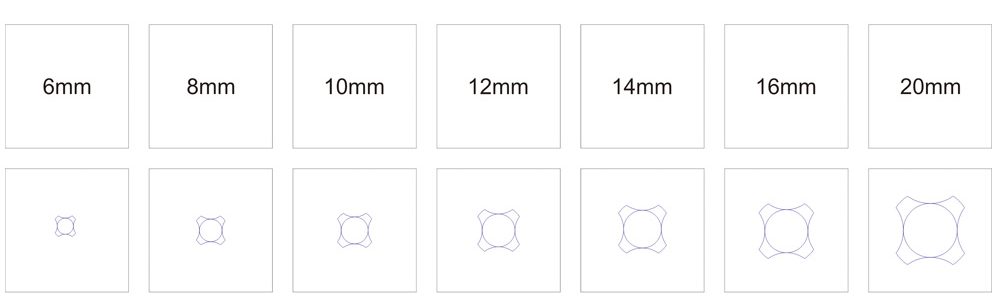

*Metal Dome: The size ranges from 4.0-24mm. The load also ranges from 180G-800G. Brands include HungHing, Nicomatic and Snaptron.

Which Metal Dome is better to choose?

In terms of life span, Nicomatic and Snapton can reach 5,000,000 drives. And Hunghing can only reach 1,000,000 drives. But in terms of cost and convenience of procurement, HungHing will be more competitive. The Metal Dome also affects the resistance. The gold-plated Metal Dome has the smallest resistance, while the conventional stainless steel Metal Dome has the highest resistance. The medical and military industries generally use nickel-plated or gold-plated Metal Dome.

*LEDs: Different brands of Mcd and wavelength have different, but the general life span can be as high as 10,000-30,000 hours. At the same time, some LEDs with Zener are more beneficial to resist resistance. The MCD of Backlight Solution lamps is generally very high. The highest are white LEDs.

*Terminal cover: Brands include: MICC801, BERG, CJT, NICOMATIC and other brands, and there are different choices according to customer needs.

*Resistance and capacitance: depends on the customer’s product requirements.

*Other accessories: IC or heterogeneous electronic accessories require customers to provide Jig for product testing.

Design aspect:

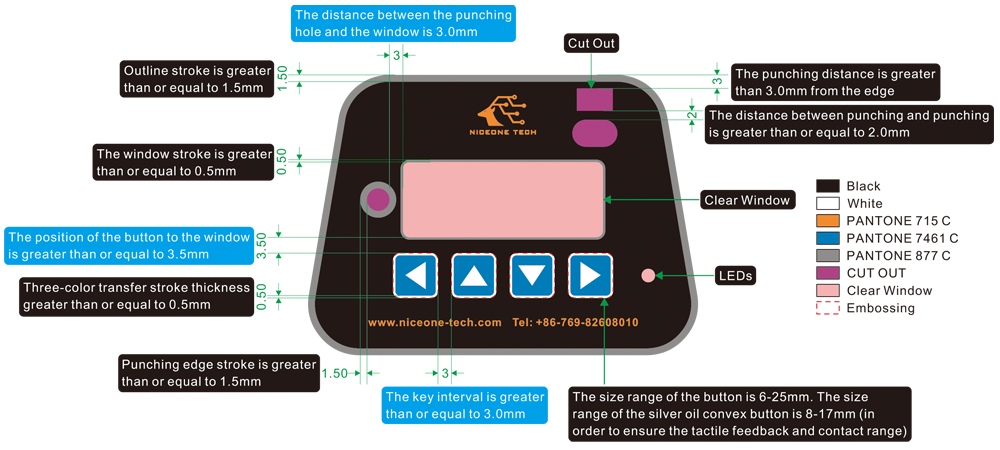

What is needed for the panel design of Membrane Switch?

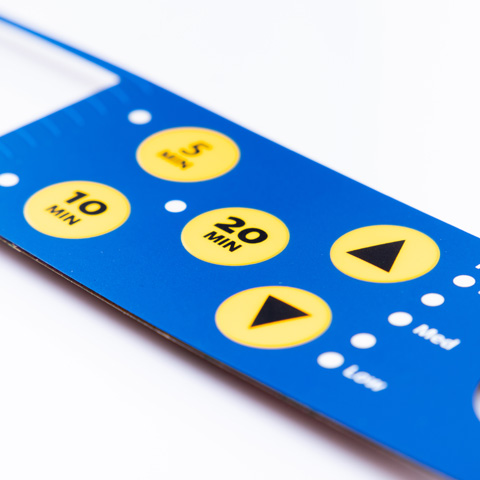

1. The detailed Pantone color number, RAL color number or Master Color can be used as a color reference template to design the color of the overlay.

2. Editable vector files. The thickness of the line needs to be greater than 0.1mm before it can be printed.

3. Consider the usage: glare, ultraviolet, antibacterial, scratch resistance, etc. need to be customized according to the situation. The problem of glare requires the use of frosted ink or frosted material, and ultraviolet light needs to consider anti-ultraviolet polyester and polycarbonate. Antibacterial This requires consideration of antibacterial materials. For scratch resistance, consider hardened materials.

4. Whether there will be problems with color overlay: A common consideration is that multi-color overlay cannot use Screen printing and needs to consider Digital Printing.

5. Cost considerations: Digital Printing or Silicone Rubber Keypad can be considered as Overlay when the quantity is large.

6. Embossing height design:

Button height: 0mm-1.3mm. The best height of Tactile Feedback of Button Embossing is 0.3-0.5mm. The height is greater than 0.5mm, and Tactile Dot needs to be added above the Metal Dome to increase the product feel.

The height of the LEDs window: 0-0.5mm. Mainly to prevent LEDs from breaking the Graphic Overlay

Blind spot height: 0.1-0.7mm. Design to reduce operating errors.

7. The Embossing shape design of Button includes:

8. Window back processing:

For OCA windows, vacuum is needed to eliminate air bubbles between the window and the PC window.

UV dots are printed on the window to eliminate Newton’s rings. It is commonly used for Membrane Switches with a PC window attached to the back of the Overlay and a large gap.

9. For the uniform color of the overlay and no other colors, it is recommended to use materials above 0.18, otherwise there will be bumps.

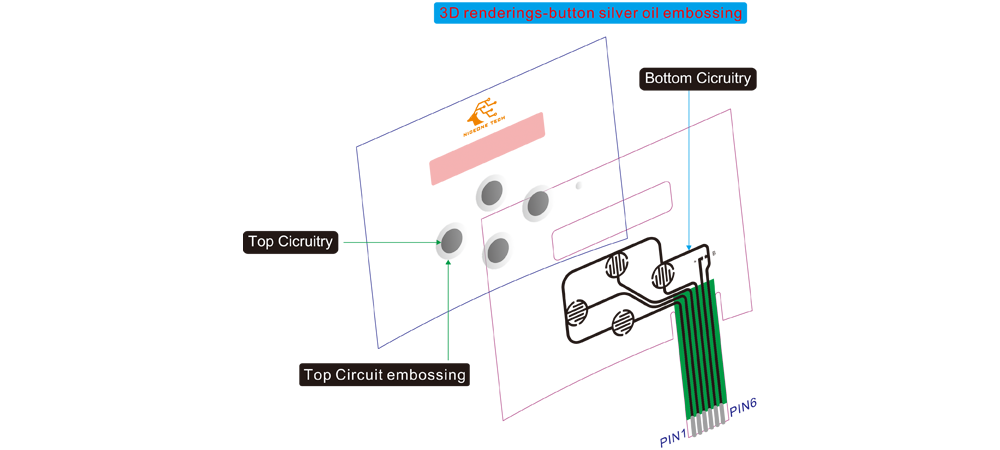

Second layer structure: What should Adhesive consider?

- The choice of thickness: 0.125-1mm, 0.175-0.225 is highly recommended, so that the Tactile Feedback of the product will be better than the other two. If it is Non-Tactile, you can choose 0.125mm or even 0.05mm is feasible, and the cost will be reduced. Metal Dome above 10mm needs to consider shrapnel above 0.225mm, Tactile is better. If it is a backlight solution and Resin Dome structure, you need to choose 0.5-1mm foam tape.

- Exhaust problems and bulging: At this level, you need to consider opening the exhaust holes to ensure the Tactile Feedback of the keys and the resolution of the scheduling problems. The bulge problem is also caused by the inconsistency between the gas inside the button and the outside.

- If the product uses Silicone Rubber Keypad, you need to consider silicone discharge or special use of Adhesive.

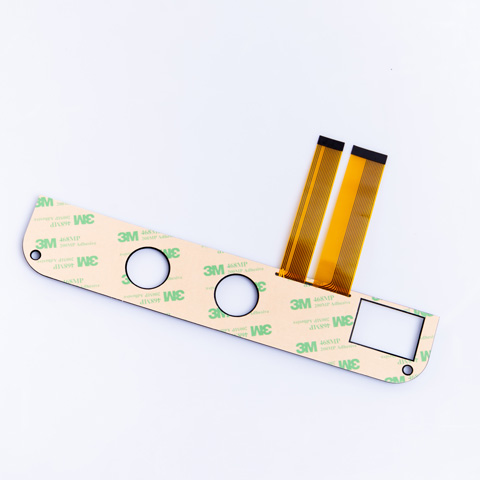

The third layer structure: What factors need to be considered for Dome Retainer?

- Electrostatic shielding: Since Membrane Switch is often damaged by static electricity, the electronic function is lost. The common practice is to print a full-page silver oil shield or use PI materials to protect the Membrane Switch from electrostatic breakdown and loss of electronic functions. The general thickness is 0.075-0.125mm.

- It can be used as the upper line layer of the circuit, where silver dots or half circuits can be printed. This kind of Membrane Switch has no shrapnel or even bumps, and the cost is low.

Fourth layer structure: Circuit Adhesive

Basically the same design ideas as the second layer.

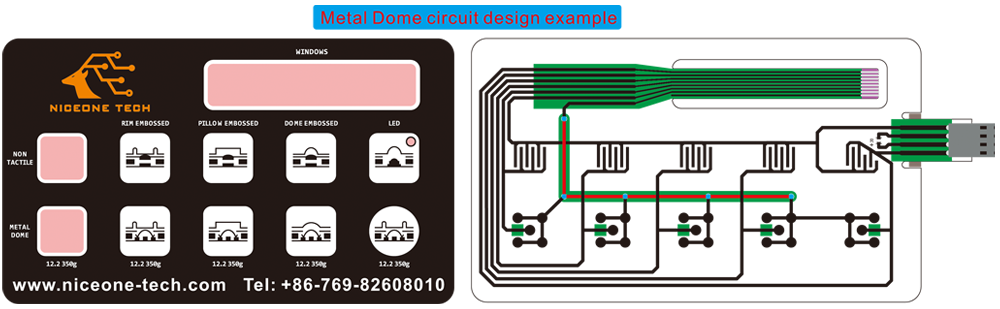

Fifth layer structure: What should be considered for the route?

You can refer to the Circuit of Membrane Switch, please click here.

Sixth layer structure: What needs to be considered for Backside adhesive?

It depends on the material to be bonded: stainless steel, plastic or aluminum.

What are the upgrade designs of Membrane Switch?

1. ESD/RFI/PI: Effectively avoid the static electricity problem of Membrane Switch.

2. Backlight technology: It can make the buttons and logo of Membrane Switch shine.

3. Blind spot embossing: reduce key operation errors.

4. Resin Dome: Make the product more aesthetic performance.

5. Capacitive design: increase product life and reduce product unit price.

6. Plug-in type: reduce mold cost.

7. Silicone Rubber Keypad surround type: Waterproof performance is greatly improved

8. OCA: The bonding of the PC window and the panel without air bubbles is different from the regular panel printing dots.

9. Brushed metal design: more modern aesthetics

10. Fit to various backplanes: reduce customer assembly time and increase product thickness

11. Digital Printing: Let your products have gradient colors.

12. Metallic panel design: use mirror silver or brushed material.

13. Combination with touch screen: The combination of OCA and touch screen often appears in Membrane.

More design improvements can be negotiated with Niceone-Keypad to make your Membrane Switch more competitive

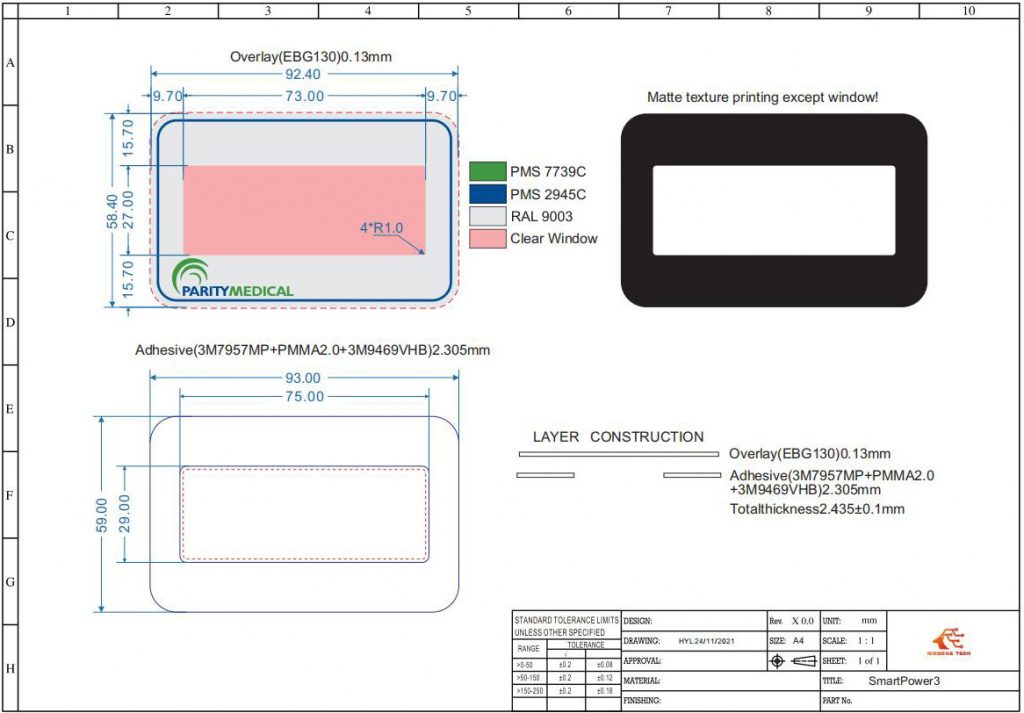

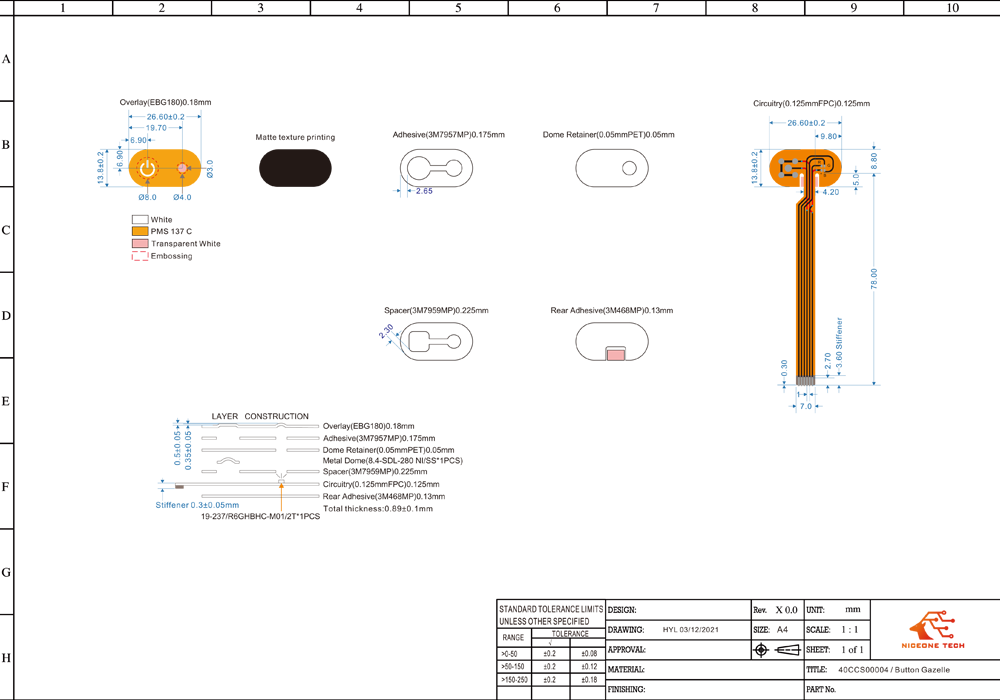

Prepare a suitable customer’s plan and perfect the design drawing for the customer to confirm:

After the customer understands its needs, the choice of product materials, whether to choose a high value-added design and cost estimation, we can design the drawings. The time for designing drawings is generally 1-7 days according to the completeness of the drawings. The best customer drawing is to show three contents to Niceone-Keypad designer:

- Editable vector graphics

- Accurate color coding or customer sample color card.

- Complete circuit principle and corresponding panel buttons, PIN1 position, outlet and corresponding positioning size.

Our drawings fully reflect the above three points. If your drawings do not have these information, we can draw according to your needs.

How to ensure that your Membrane Switch gets a high-quality guarantee-Membrane Switch detection?

Silk screen part:

Niceone-Keypad also needs to do (the silver oil line is also tested in strict accordance with the following requirements):

1. Check the film and template of the printed pattern;

2. Check whether the color meets the requirements of the template or color number;

3. The printed text and pattern must be clear, without blur, ghosting, or jagged;

4. Pay attention to the blocking of the net, foreign matter, oil, and scraper during the printing process Marks, sticky nets, inaccurate sets of positions, etc.;

5. Ink adhesion inspection.

Stamping part:

1. When drilling the pipe position hole, pay attention to the center position of the pipe position hole, and don’t make the deviation;

2. Check the embossed product against the sample plate for deviation, and do related tests;

3. Check whether the pipe position hole is offset.

4. Check whether the convex position of the product after hot pressing and convex is deviated, indentation, etc.;

Fitting part:

1. Correctly attach the adhesive tape according to the template and process;

2. Pay attention to air bubbles, dust, foreign matter, and deviation when attaching adhesive tape;

3. Pay attention to cooperating with other departments during the whole lamination process.

4. Whether the correct adhesive tape is attached;

5. Check for problems such as bubbles, dust, foreign matter, and deviation after bonding.

Appearance inspection part:

1. Pay attention to the inspection panel not to have black spots, nail marks, oil stains, white spots, indentations, etc.;

2. Check whether the pasting glue is well and correctly pasted

3. If there is oil on the panel, be careful not to have oil, dust and other sundries on the surface;

4. If there is a panel that is manually stamped, hot pressed, and convex, check whether the convex position is offset, etc.;

5. Packaging inspectors should pay attention to the inspection while not scratching the panel with their fingers.

Line function part:

According to the actual drawings, it mainly detects resistance, electrical function, circuit principle and short circuit and open circuit problems.

Extended part

Overlay:

The Overlay of Membrane Switch needs to be tested for 4 times: A. Before printing, it is necessary to check whether the panel material is selected according to the production documents, and perform a 100-grid test to check the ink adhesion. B. After printing, you need to check again whether the color number of the color meets the requirements of the drawing, and whether there is trachoma and light transmission. C. It is necessary to check whether the ink is peeled and scratched when embossing. D. Check whether the Overlay is scratched after mounting.

Tactile Feedback:

- Tactile Feedback test: Tactile Feedback test needs to pay attention to the height of the button, and select the appropriate metal load and stroke. The selection of molds, the selection of structures and the vents all require pre-production evaluation during the drawing process to avoid various problems. QC testing also needs to pay attention to the Tactile Feedback test, unless it is a Non-Tactile Membrane switch without any hand feeling.

- Membrane Switch circuit function test: Whether the resistance is too large, whether the electrical function is realized, and short circuit and open circuit problems need to be tested.

Backlit solution:

*Whether the light source is evenly illuminated on the part that needs to be lit.

Resin Dome:

1. Resin buttons are free of any impurities.

Problems and solutions that will occur in Membrane Switch:

- Does the color need to be gradual and too many colors: Digital Printing

- Whether the Membrane Switch is used in a high-voltage electrostatic environment (silver migration): 1. PI, RFI, ESD, etc. as the fixed layer 2. Select Flex Copper Circuit and Printing Circuit Board as the circuit.

- Use and storage environment: The main impact is that the use and storage environment of Membrane Switch made by Adhesive, 3M adhesive can reach -25-80 degrees Celsius, while DT and Nitto adhesive tapes are usually 10-80 degrees Celsius and cannot be used at low temperatures.

- Membrane Switch appears Newton’s ring: use OCA technology or UV dots printed between the PC window and the Overlay.

- Scratches appear in the Membrane Switch window: Use hardened polycarbonate material for the panel or window, or use EBGmaterial as Overlay.

- The resistance of the Membrane Switch is too high: the line is too long, and the Metal Dome needs to be plated with NI or GOLD. The best solution is to use Flex Copper Circuit or Printing Circuit Board.

*The tactile feedback of Membrane Switch is poor: Metal Dome needs to choose a suitable load, and the thickness of the Overlay material needs to be 0.125-0.2mm and it needs to be convex. Adhesive of 0.3mm or less should be selected for the surface adhesive layer.

*Membrane Switch function short circuit: Whether the silver oil circuit is fuzzy or short circuited. Metal Dome is off.

*The lead wire of Membrane Switch should be scratched by the electronic components, causing the circuit to be short-circuited: The circuit can choose to mount Mylar to solve the problem. Choose Flex copper circuit.

*Metal Dome offset of Membrane Switch: Metal Dome fixture is required for the factory mounting process.

Packaging of Niceone-Keypad:

- The thread end can use paper label or pad printing label to add product PN, PO and Date.

- The label of the outer box allows customers to understand the quantity and date of each box, and can trace the product to the source.

- The use of foam reduces product collisions.