Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By hqt

BOPLA expands its range of input units with the new capacitive membrane switch keypad. These have excellent properties of resistance to acids, dirt, and other types of impurities, and withstand high mechanical loads. The surfaces are easy to clean and are therefore suitable for working in particularly demanding environments in terms of hygiene.

The interface between operator and keyboard is not mechanical and therefore there are no mechanical keys. The activating element is different from the user by a smooth surface. This considerably simplifies the cleaning of the keyboard.

And allows not only its use in areas subject to the risk of vandalism but makes it particularly suitable for applications that are particularly demanding in terms of hygiene (medical equipment or in the food industry)..

The lack of tactile response to actuation is easy to replace by an optical and/or acoustic signal. membrane switch keypad and switches with capacitive effect easy to make both as individual keys and as an array of keys for which any shape is approve. This allows ample freedom of expression in design and graphic customization.

The sensory surface of the button comes up of two areas isolated from each other (the transmitter electrode and the receiver electrode). On the sensor side, oscillations are generated which are in turn transmitted to the receiver electrode by capacitive coupling.

When the finger touches the screen, the capacity of the human body adds causing a change in the surface capacity. The signals are attenuated and through this attenuation, the electrical impulses are detected and processed.

Digital filters and special algorithms ensure that any interfering signals, even short ones, and slow variations cannot cause malfunctions.

The complete capacitive control unit consists of three elements: capacitive sensors, processing electronics, and the actual interface (usually in glass or Plexiglas).

However, whenever membrane switch keypad backlighting requires or the surface needs to bend, the PCB obviously cannot be placed directly under the screen. In this case, the use of a separate sensory membrane is recommended.

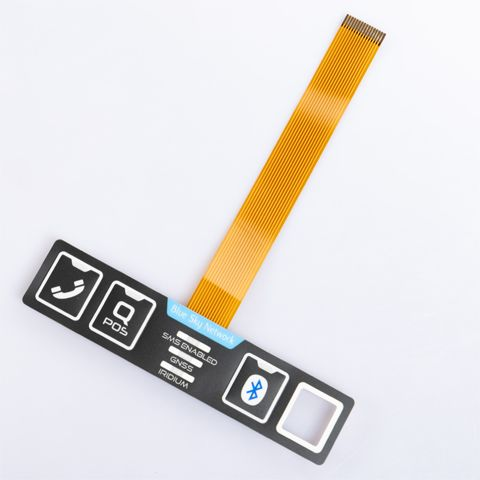

In these cases, the sensory surfaces are applied on a polyester membrane by silk-screen printing and connected with the electronics using the flat membrane cable. On this level there, are also the LEDs which, position at a certain distance, actuate a

The classic membrane keyboard is built by superimposing up to eight layers of which, in practical use, only the upper/external one will be seen, the so-called front membrane (decorative film). This front membrane comes according to the specific indications and needs of the customer.

Under this outermost layer, there are, depending on the technology adopted, further layers such as:

This allows you to apply the membrane switch keypad on the case.

Among all these different layers, there is the real “heart” of the membrane keyboard: the metal dome

Backlit profile – Detail of the construction structure

Which membrane keypads offer a good tactile response with a clear click when pressed?

Although touch screen applications are very trendy, classic membrane keypads with a good tactile feel and a clear Snap-On pressure are more in demand than ever. For this type of use, for example, membrane switch keypad proves to be perfectly suitable, establishing themselves thanks to the following characteristics:

The membrane keypads are capable of satisfying the most stringent requirements regarding tactile sensitivity and ergonomic properties. The input interface comes by the typical “short stroke” feel and an ideal “tactile guidance” for the fingers.

The design of the membrane keypad. And the number/shape of the keys fully conforms to the wishes. And needs of the customers. It is therefore possible to make both extremely small keys. And very large keys. The keys, which transmit strength. And release a good tactile sensation, position between the metal dome and the front membrane.

They therefore not only convey a good tactile response to pressure but are also extremely robust. In addition to offering the usual protection against dust and humidity, the acrylic insert also protects the metal dome from possible deformation. Not even the action of strong and point-like pressures can damage the surface of the membrane switch keypad of the input systems.

By making the inserts accordingly, we can satisfy, with our keypads, even the most specific wishes regarding the highest safety requirements in the use of equipment and machinery. Among these we have for example:

The double contact simplifies the operator’s work by giving him the possibility to recognize two different logic states. This function allows you to create even circuits against single anomalies (redundant) that prescribe for applications that must meet strict safety requirements.

With what printing methods is it possible to create membrane keypads with customized layouts?

Our membrane switch keypad comes in screen printing or digital printing according to the requirements, wishes, and type of graphics. Based on the criteria mentioned below, we together with the customer choose the most suitable printing method for their membrane keyboard.

Example screen printing

Digital print

Do you have any questions, or would you like to speak directly with a representative?