Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By hqt

When it comes to membrane switch production, precision and efficiency are key. Two popular methods used in the industry are laser cutting and mold cutting. Both techniques have their advantages and disadvantages, and understanding them can help you make an informed decision for your specific project. In this article, we will delve into the differences between laser cutting and mold cutting in membrane switch production, highlighting their pros and cons. So let’s dive in!

Laser cutting is a precise and versatile method commonly used in various industries, including membrane switch production. It involves using a high-powered laser beam to cut through the material, allowing for intricate designs and complex shapes. Here are some key points to consider when it comes to laser cutting in membrane switch production:

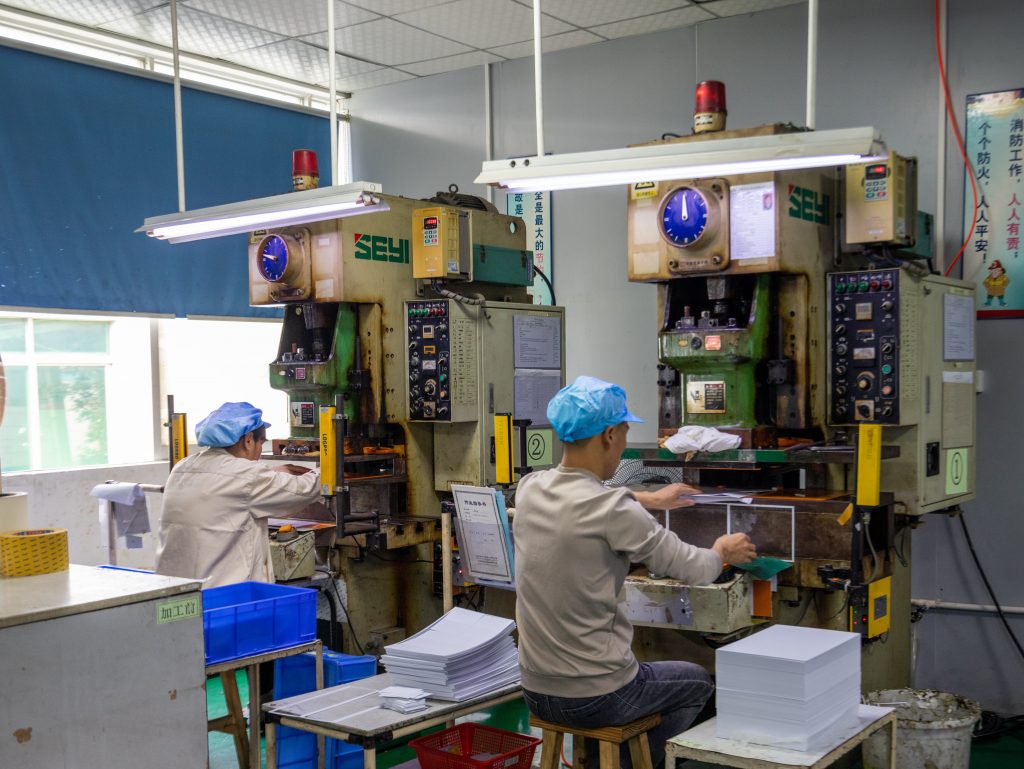

Mold cutting, also known as die cutting, is a traditional method commonly used in membrane switch production. It involves using a mold or die to cut through the material, creating the desired shape. Let’s explore the advantages and disadvantages of mold cutting in membrane switch production:

1. Is laser cutting or mold cutting better for membrane switch production?

Both laser cutting and mold cutting have their advantages and disadvantages. Laser cutting offers precision, versatility, and minimal tooling costs, while mold cutting is cost-effective for large production runs and suitable for thicker materials. The choice depends on your specific project requirements, material properties, and budget considerations.

2. Can laser cutting be used for heat-sensitive materials in membrane switch production?

Laser cutting generates heat during the process, which can be a concern for heat-sensitive materials. It is crucial to consider the material properties and consult with experts to determine if laser cutting is suitable for your specific heat-sensitive material in membrane switch production.

3. Does mold cutting allow for intricate designs and complex shapes?

Mold cutting has limitations when it comes to intricate designs and complex shapes. It relies on physical molds or dies, which may restrict design flexibility compared to laser cutting. If your project requires intricate designs, laser cutting might be a more suitable option.

4. Which cutting method is more cost-effective for small-scale membrane switch production?

Laser cutting tends to be more cost-effective for small-scale membrane switch production due to its minimal tooling costs. It eliminates the need for expensive molds or dies, making it a viable option for projects with limited budgets.

5. What factors should be considered when choosing between laser cutting and mold cutting?

When choosing between laser cutting and mold cutting, consider factors such as precision requirements, material properties, design complexity, production volume, lead time, and budget. Evaluating these factors will help you make an informed decision based on your specific needs.

6. Can laser cutting or mold cutting be used for other applications besides membrane switch production?

Both laser cutting and mold cutting are versatile techniques used in various industries besides membrane switch production. Laser cutting finds applications in industries like automotive, aerospace, electronics, and signage, while mold cutting is commonly used in packaging, automotive, and textile industries.

In the realm of membrane switch production, both laser cutting and mold cutting have their merits. Laser cutting offers precision, versatility, and speed, while mold cutting is cost-effective for large production runs and suitable for thicker materials. Choosing between the two methods depends on your specific project requirements, material properties, design complexity, production volume, lead time, and budget. By considering these factors, you can make an informed decision that aligns with your goals. So, whether you opt for laser cutting or mold cutting, you can achieve high-quality membrane switches that meet your needs.

Do you have any questions, or would you like to speak directly with a representative?