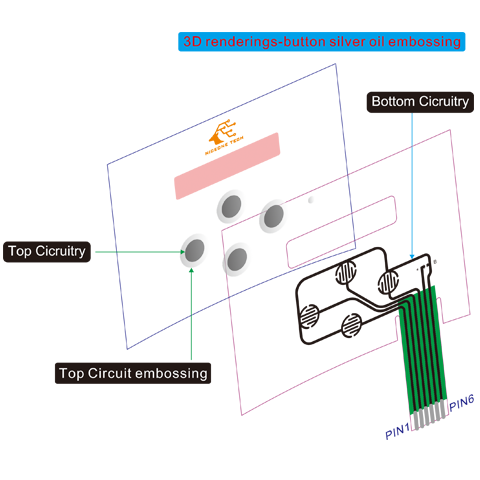

Conventional design ideas for Membrane Switch

A summary of the common key points of the Niceone-Keypad factory membrane switch product process and design specifications.

-

1. Overlay graphic design considerations:

Key points of Membrane Switch design:

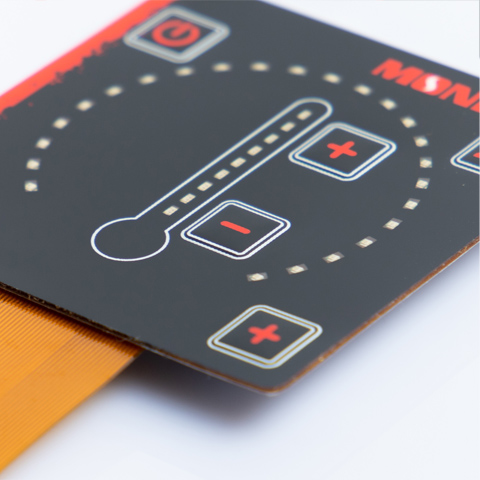

The first impression of a membrane switch is often the Overlay, and a good Overlay can make a deep impression. In Niceone-Keypad, there are mainly two types of printing: Silk Screen Printing and Digital Printing. However, there are many factors that need to be considered in the process of graphic design so that customers can realize the design process. At the same time, another benefit is that it can be more suitable for factory production to improve product design speed and reduce user production costs.

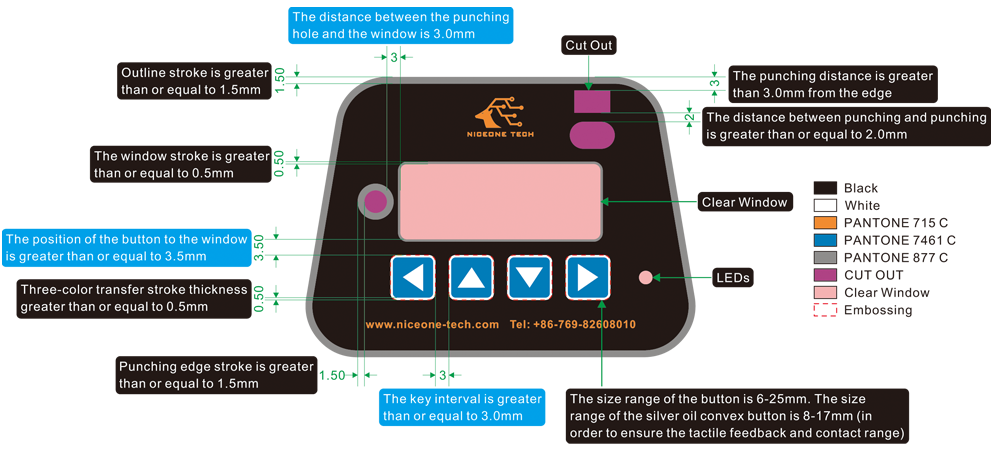

Membrane switch shape and silk screen parameter design

External dimension tolerance: ±0.2mm (hardware molds can be 0.1mm, but the relative cost increases a lot) Button stroke line width needs: ≥0.4mm (three-color handover ≥0.5mm. Color printing does not have such problems, but the color deviation of different batches of color printing is large) Minimum text pattern line width: ≥0.2mm Button bump spacing: ≥3mm Outlet from edge: ≥0.7mm (it is not recommended to exit the line at the edge) with waterproof requirements, preferably >5mm Embossing height: 0.3~0.8mm Biggest size: 1.2m*400mm Appearance/Cut out safe distance from silver paste line: ≥0.7mm Minimum silver paste line width: ≥0.5mm (if FPC or PCB circuit is used, it is not limited to ≥0.5mm) The following table shows some design points of Membrane Switch:

- Outline stroke is greater than or equal to 1.5mm

- The window stroke is greater than or equal to 0.5mm

- The distance between the punching hole and the window is 3.0mm

- The punching distance is greater than 3.0mm from the edge

- The distance between punching and punching is greater than or equal to 2.0mm

- Three-color transfer stroke thickness greater than or equal to 0.5mm

- The position of the button to the window is greater than or equal to 3.5mm

- The key interval is greater than or equal to 3.0mm

- Punching edge stroke is greater than or equal to 1.5mm

- The key interval is greater than or equal to 3.0mm

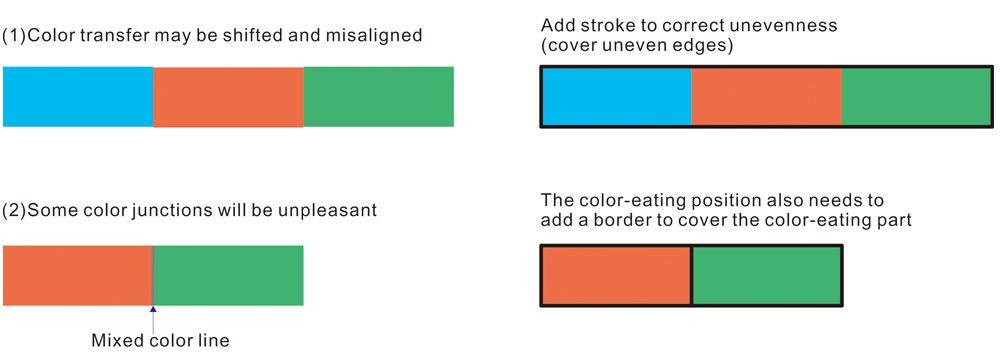

Below are some color overlay processes of Silk Screen Printing:

Picture color overlay (Silk Screen Printing)

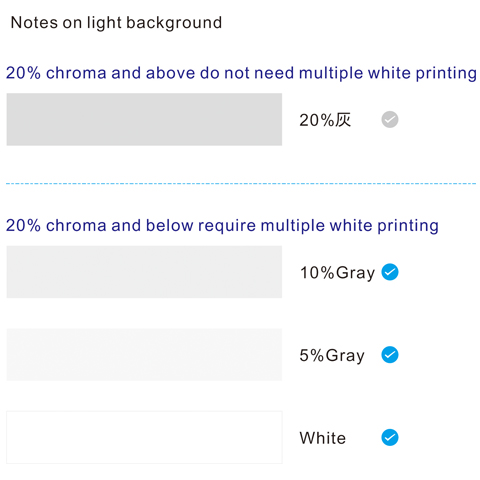

Silk Screen Printing’s light colors and Digital Printing need to print white or gray to increase its occlusion effect. When the Membrane Switch is equipped with LEDs, it is even necessary to print three times of white and one additional gray to increase its light blocking effect. Otherwise, the lighting effect of LEDs will cause the phenomenon of Light Bleed on the edges. Light colors are generally as follows:

Niceone-Keypad acceptable color color system: RAL, PANTONE COLOR, CMYK (but the color error is very large, not recommended. Generally color printing uses ai. document) or sample (color printing samples are not accepted because of the large color error of color printing samples). However, some special color numbers require customers to send samples or color cards for printing.

About Silk Screen Printing and Digital Printing of Membrane Switch:

Silk Printing is a printing method with the smallest color error, suitable for small batch production. The general printing method is to print on the back of the product to increase the life of the product. The choice of color is mainly from RAL, PANTONE two types of color number selection.

Digital Printing allows Graphic Overlay with color gradient effect, and is suitable for mass production to reduce the cost of Graphic Overlay.

Specific process

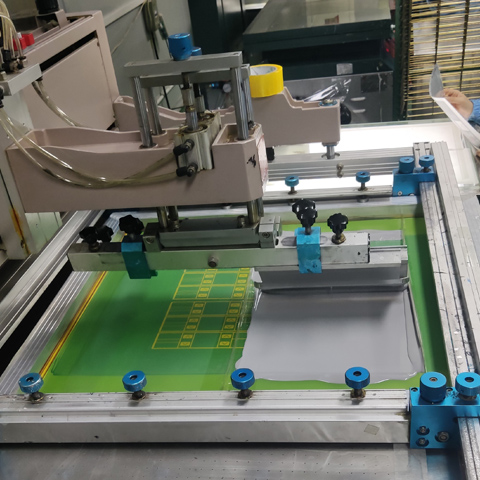

Silk Screen Printing uses silk screen printing as the basic version. Pass the required logo and graphics through a photosensitive plate making method, so that the ink can pass through the basic plate base and then use a squeegee to apply appropriate pressure to the ink. The required patterns and logos will be realized on the overlay. Similarly, the circuit is also printed and manufactured using Silk Screen Printing. The printer uses a fine metal mesh (usually a layer of polyester or silk) to make a template with various effects through which the ink will be pressed onto the underlying substrate. According to the number of colors, the number of screen bases is also different.

Advantages of Silk Screen Printing Membrane Switch:

- Small color error (compared to Digital Printing).

- Different inks can be used according to different materials.

- Since the ink is generally printed on the back of the product, it is suitable for outdoor display or outdoor use without causing too much impact on the product.

- Better adhesion.

- Not limited by the size and shape of the substrate.

- Most colors are thicker.

However, the more colors of the product, the more processes required for photo-sensing plate making, and the cost will increase accordingly. If out of cost considerations, Niceone-Keypad sometimes recommends customers to use Digital Printing.

The specific process flow of Digital Printing:

Digital printing is actually the process of directly using customer-provided files (such as AI or PDF files) to input the device, using CMYK to collide the required colors, and the process of sending information from the device (such as a computer or portable storage device) to the printer is created by graphics software. However, due to the simplified process of color printing, there is no need to create a screen for each color, so it is particularly suitable for mass-produced Membrane Switch.

Advantages of Digital Printing Membrane Switch:

- It is suitable for mass production, and the cost is greatly reduced.

- Colors can be made into gradient colors, 3D graphics, textures, etc. Silk Screen Printing can’t do it.

- It is not limited by the size and shape of the substrate, and the color printing size is larger.

Digital Pringting Membrane Switch still needs additional Silk Screen Printing after printing. At this time, because the overlay color from Digital Printing is not thick enough and transparent, the form of Silk Screen Printing needs to be used to increase the thickness of the product.

-

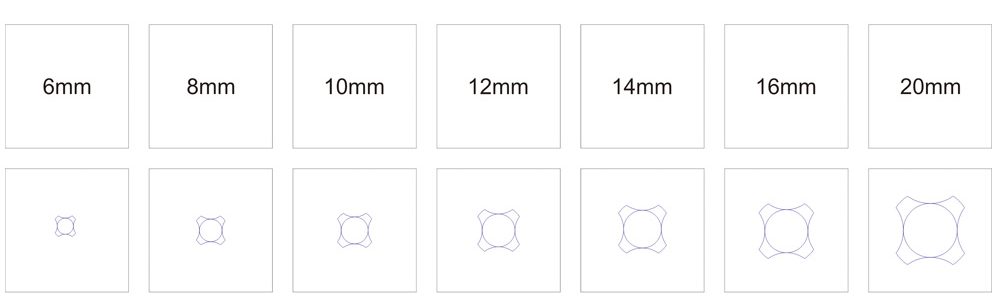

2. Embossing

Most of the buttons of Membrane Switch are attached with Embossing. Embossing has more shapes, mainly as follows.

Embossing’s main function has two points:

1. Played an instructional role.

2. Increased Tactile Feedback.

3. Improved recognition.

The most obvious design for adding Tactile Feedback is when Membrane Switch has no Metal Dome design. The silver paste disc of the button on the circuit is pressed into a predetermined spherical crown with a mold, and the same is true for the panel. Although the cost of the mold has increased, the unit price of the product has dropped a lot. The size of Embossing is 5-11mm, but 8-10mm is more recommended.

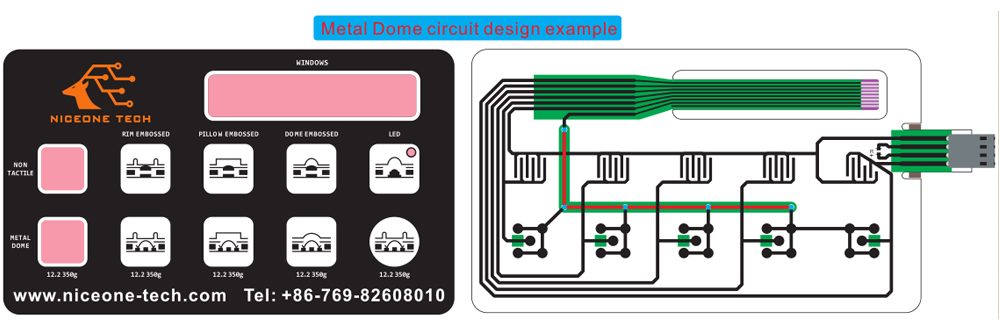

If the Membrane Switch chooses Metal Dome instead of using silver dots to conduct, there will be more benefits. The conduction performance is stronger, the rebound will be stable, the Tactile Feedback will be better, and the life span can reach 1,000,000 times, relatively speaking.

- Common brands of Metal Dome: Nicomatic, HungHing or Snaptron (Supplied by Customer) etc.

- Common coatings of Metal Dome: SS, Ni or Gold. (It is best to choose Ni or Gold, which is conducive to the stable performance (resistance) of the product)

- The size of Metal Dome is generally: 6, 8.4, 10, 12, 14, 16mm (8.4-12mm is the best choice, because the size is similar to the size of the finger.)

- The shapes of Metal Dome are: circle, triangle and cross. What Niceone-Keypad uses is a stainless steel cross Metal Dome.

Metal Dome: The size ranges from 4.0-24mm. The load also ranges from 180G-800G. Brands include HungHing, Nicomatic and Snaptron.

-

3. About the Adhesive:

Niceone-Keypad will select different adhesives according to the needs of users. Commonly used adhesive tape brands are DT, 3M or Nitto adhesive. According to the way of use, cost considerations, etc., the following two situations are divided:

- If the Membrane Switch is used in extreme environments, such as -20 degrees Celsius to 100 degrees Celsius, then 3M and Nitto Adhesive need to be considered. Because DT Adhesive can only be used in 10-80 degrees Celsius.

- If you consider the cost factor, DT adhesive has the lowest cost, followed by Nitto Adhesive.

But 3M Adhesive is the most commonly used adhesive tape for Niceone-Keypad. Specific 3M models are 3M467, 3M468, 3M7957, 3M300LSE, 3M9448AB or 5925VHB. How are they different?

Color

Temperature Range

Peel Strength

3M467 transparent 149℃(long term)~204℃(short term) 5.5N/10mm It has excellent bonding effect, can prevent falling off, has waterproof performance, good processability, good temperature resistance, and good adhesion; the release paper is a polymer-coated waterproof kraft paper.

It will not wrinkle in a high humidity environment, and has good temperature resistance (repeated sticking is not recommended). It is usually used as a back glue. Most of the time it is also used in Overlay Adhesive of capacitive Membrane Switch.3M468 transparent 149℃(long term)~232℃(short term) 8.5N/10mm The thickened version of 3M467MP has excellent bonding effect, can prevent falling off, and has waterproof performance, good processing, good temperature resistance, and good adhesion; the release paper is polymer-coated waterproof kraft paper, which can be It will not wrinkle in a wet environment, and it has good temperature resistance (repeated paste is not recommended). It is usually used as a back glue. Most of the time, it is also used in Overlay Adhesive of capacitive Membrane Switch. 3M7957 transparent 149℃(long term)~204℃(short term) 5.5N/10mm Similar to 3M467, only the middle is the difference between the attached substrate, the thickness of the PET substrate is 0.075mm and the total thickness is 0.175mm. 3M7959 transparent 149℃(long term)~204℃(short term) 5.5N/10mm Similar to 3M467, only the middle is the difference of the attached substrate, the thickness of the PET substrate is 0.125mm and the total thickness is 0.225mm. 3M7961 transparent 149℃(long term)~204℃(short term) 5.5N/10mm Similar to 3M467, only the difference between the attached substrate is in the middle. The thickness of the PET substrate is 0.175mm and the total thickness is 0.275mm. 3M9448AB black 80℃(long term)~120℃(short term) 5.5N/10mm The thickness is 0.15mm, the viscosity is also very good, and the adhesion at low temperature is also satisfactory. Scope of application: metal, nameplate, rubber, plastic, etc. Niceone-Keypad uses the 3M9448AB as one of the Adhesive options for the Backlight Membrane Switch, due to its ability to prevent light transmission. 3M300LSE transparent 93℃(long term)~149℃(short term) 9N/10mm 3M™ Adhesive 300LSE is a high strength acrylic adhesive that provides very high bond strength to most surfaces. Excellent adhesion to low surface energy substrates including powder coatings and plastics such as polypropylene (PP). High adhesion to metals and high surface energy materials makes it suitable for bonding dissimilar substrates . The adhesive has excellent retention and lift resistance. Good resistance to industrial chemicals, consumer chemicals, moisture and humidity. If you have higher requirements for waterproofing, you can choose 3M300LSE. 3M5925VHB black 149℃(long term)~204℃(short term) 9N/10mm Compared with 3M9448AB, the thickness is thicker and the adhesion is better. Niceone-Keypad uses 3M5925VHB as one of the Adhesive options for Backlight Membrane Switch, due to the effect of preventing light transmission. If the button is too close to the edge to worry about opening, then you will not choose 3M9448AB and consider 3M5925VHB. -

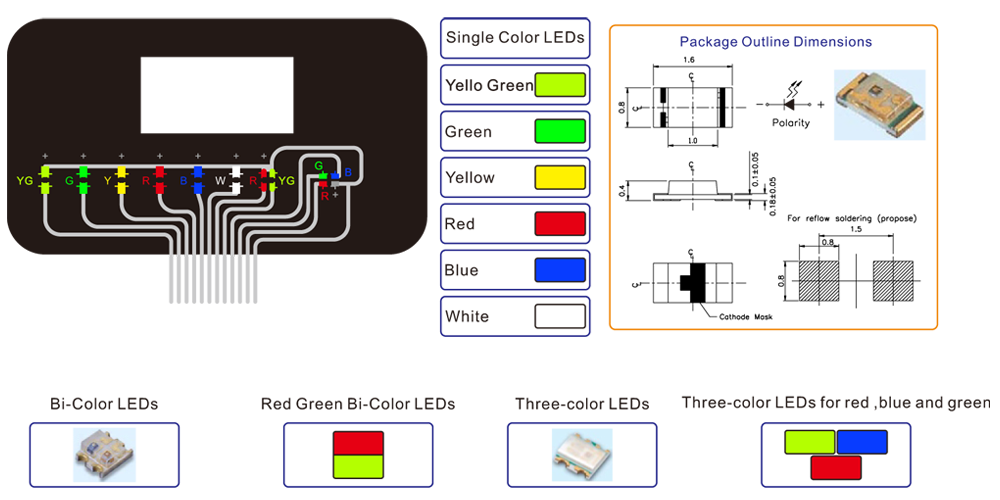

4. The color of LEDs and design ideas

The models of LEDs generally have surface mount types of 0603, 0804, and 1206. Commonly used brands are: Everlight, Kingbright, etc. The window of LEDs is generally 3-4mm.

Single Color LEDs: Red, yellow, blue, emerald green, yellow-green, orange.

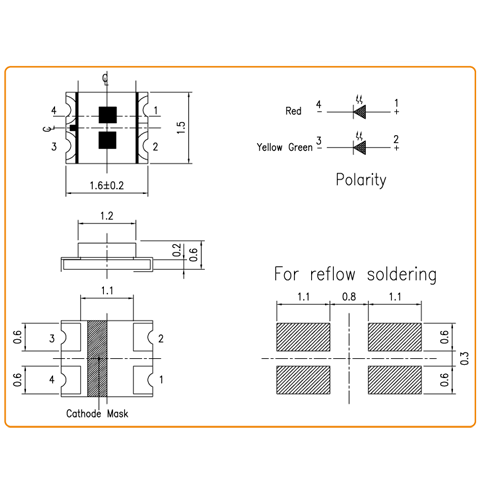

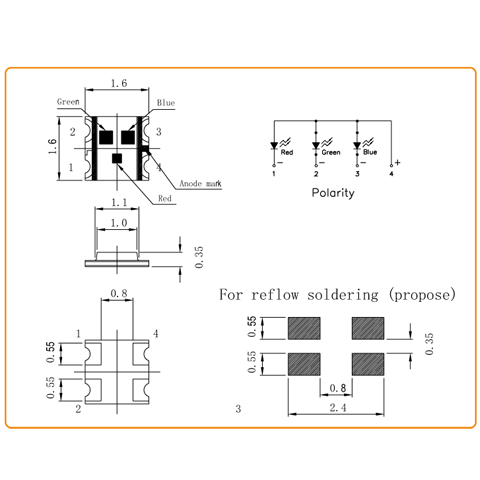

Bi-Color LEDs: Red and green.

Three-Color LEDs: Red, green and blue (also can be adjusted to different colors through IC).

If it is a popular Backlight Membrane Switch, we will choose LEDs with higher brightness. The brightness is determined by MCD. Generally, the operating voltage and current of a single LED is 3V, 20ma. If you have any special requirements, please contact Niceone-Keypad. But sometimes two-color lamps can use two different colors of single-color LEDs to complete the two-color function.

-

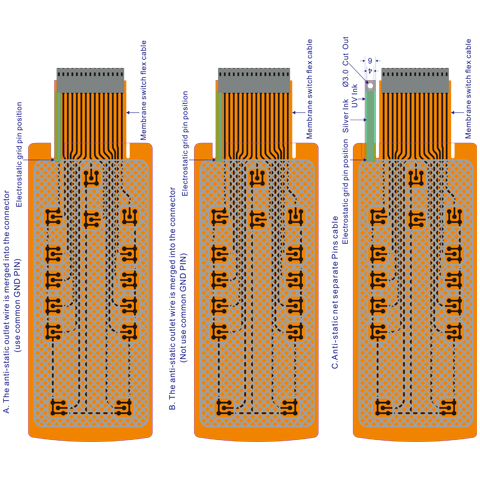

5. Key points of ESD/RFI design of Membrane Switch:

The electrostatic net of Membrane Switch is often used to protect the circuit function from being disturbed by static electricity, which leads to loss of function. At the same time, electromagnetic shielding is used to shield the space electromagnetic interference to avoid electromagnetic interference. The material of the anti-static shielding layer is generally PET printed full-surface silver oil or PI. There are 3 common designs.

-

6. Panel material selection of Membrane Switch:

Common materials for panels: PMMA, PET or PC. According to the surface treatment, it can be roughly divided into: Matt or Gloss.

Generally speaking, frosted materials with windows need to be printed with window ink, while glossy materials require additional frosted ink in addition to windows and buttons.

If you have any questions or want to know, you can contact Niceone-Keypad at any time, and we will reply to you within 24 hours.