Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By hqt

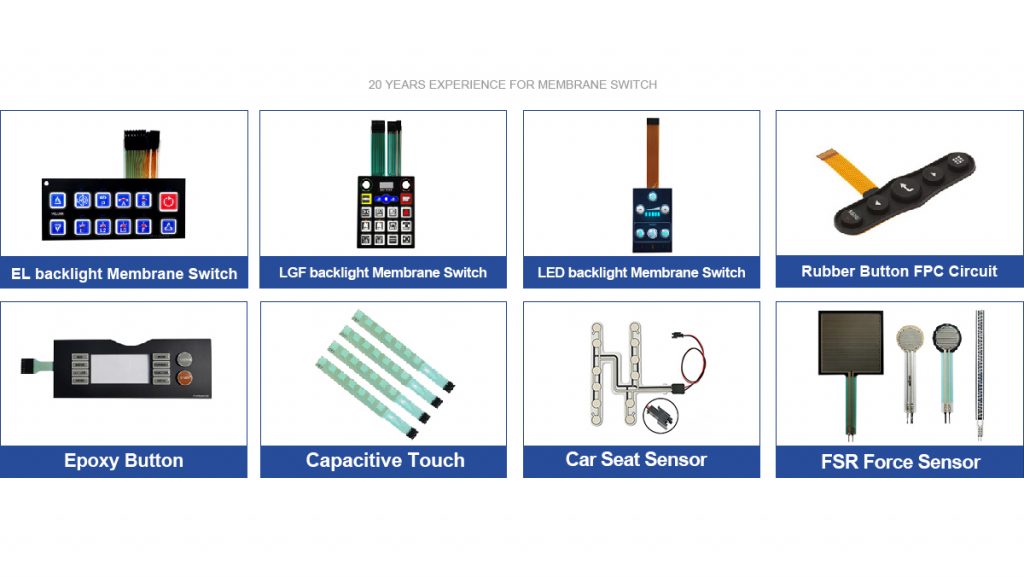

Membrane switches are a great way to take your product design to the next level. They are commonly used in a wide range of products, from medical equipment and appliances to consumer electronics and more. But what makes them so special and how can they help you achieve the best results? In this blog, we’ll explore the advantages and disadvantages of membrane switches, the different types available, and how to choose the best membrane switch for your product. We’ll also provide tips for integrating membrane switches into your product design, along with a look at the manufacturing processes and cost-effective and reliable membrane switch suppliers. Finally, we’ll discuss troubleshooting and maintenance of membrane switches.

Membrane switches are electrical switches used to control the operation of electronic devices. They are made from a flexible plastic sheet with an array of electrical contacts printed on it. When pressed, the contacts make an electrical connection, closing the circuit and activating the device. Membrane switches are popular because they are durable, reliable, and easy to use. They are also cost-effective and can be customized to fit any product design.

Membrane switches are ideal for a wide range of products and applications. They are used in medical equipment, home appliances, consumer electronics, and more. They can be used to control complex systems, such as HVAC systems and security systems, where several switches are needed to perform a single function. They are also used in products where a clean, streamlined look is desired, such as audio equipment or automotive dashboards.

Membrane switches provide a number of benefits. They are easy to use and require minimal force to activate, making them ideal for applications that require frequent use. They are also cost-effective and can be custom-designed for any product. Additionally, they are durable and reliable, so you don’t have to worry about them breaking down or wearing out over time.

The most important benefit of membrane switches is their durability. They are designed to withstand a wide range of conditions, from extreme temperatures to harsh chemicals. They are also waterproof and dustproof, making them ideal for outdoor applications. Additionally, they are resistant to shock, vibration, and EMI interference, ensuring the circuit is not affected by external sources.

Membrane switches are also easy to use and require minimal force to activate. This makes them ideal for applications such as medical equipment, where frequent use is required. Additionally, they are cost-effective and can be customized to fit any product design. This makes them a great option for products where a clean, streamlined look is desired.

Finally, membrane switches are reliable and require minimal maintenance. This makes them ideal for applications where frequent use is required, such as HVAC systems or security systems. Additionally, they are simple to troubleshoot, as any faulty connections can easily be identified and replaced.

Membrane switches come in a variety of types, each designed for specific applications. The most common type is the momentary switch, which activates when pressed and deactivates when released. This type is ideal for applications that require frequent use, such as medical equipment.

Toggle switches are another popular type of membrane switch. They remain in the same state until the user manually changes it. This type is ideal for applications that require a single switch to control multiple functions, such as HVAC systems or security systems.

Finally, there are latching switches, which remain in the same state until the user manually changes it. This type is ideal for applications where a single switch needs to control multiple functions, such as audio equipment or automotive dashboards.

The biggest advantage of membrane switches is their durability and reliability. They are designed to withstand a wide range of conditions, from extreme temperatures to harsh chemicals. Additionally, they are waterproof and dustproof, making them ideal for outdoor applications. Additionally, they are resistant to shock, vibration, and EMI interference, ensuring the circuit is not affected by external sources.

The main disadvantage of membrane switches is that they are not as responsive as mechanical switches. This can make them less ideal for applications that require quick response times, such as gaming consoles or remote controls. Additionally, they are not as precise as mechanical switches, so they may not be ideal for applications that require precise control, such as audio equipment or automotive dashboards.

When choosing a membrane switch for your product, it is important to consider the type of application it will be used for. Momentary switches are ideal for frequent use applications, such as medical equipment. Toggle switches are ideal for applications that require a single switch to control multiple functions, such as HVAC systems or security systems. And latching switches are ideal for applications that require a single switch to control multiple functions, such as audio equipment or automotive dashboards.

It is also important to consider the environment in which the switch will be used. For outdoor applications, it is important to choose a switch that is waterproof and dustproof. Additionally, for applications where the switch will be exposed to extreme temperatures or harsh chemicals, it is important to choose a switch that is resistant to these conditions.

Finally, it is important to consider the cost. Membrane switches are generally more cost-effective than mechanical switches, so it is important to consider your budget when choosing a switch for your product.

Integrating membrane switches into your product design can be a challenge. However, there are some tips that can help make the process easier.

The first tip is to use an overlay or housing to protect the switch and make it easier to press. This will help ensure that the switch is not damaged by the user and will also make it easier to press. Additionally, it is important to choose the right type of switch for your application. Momentary switches are ideal for frequent use applications, such as medical equipment, while toggle switches are ideal for applications that require a single switch to control multiple functions.

It is also important to consider the physical layout of the switch. It is important to ensure that the switch is easy to reach and that the user can easily identify which switch they need to press. Additionally, it is important to make sure that the switch is easy to press and that the force required is not too much or too little.

Finally, it is important to consider the electrical layout of the switch. The switch must be connected to the appropriate power source and the circuit must be designed to handle the current and voltage requirements of the switch.

Membrane switches are made using a variety of manufacturing processes. The most common process is screen printing, where the contacts are printed onto the plastic sheet. This process is cost-effective and allows for a wide range of customizations.

Another popular process is hot stamping, where the contacts are stamped onto the plastic sheet using heated dies. This process is more precise and allows for more intricate designs.

Finally, laser etching is used for more complex designs. In this process, a laser is used to etch the contacts onto the plastic sheet. This process is more expensive but allows for more intricate designs.

When choosing a supplier for membrane switches, it is important to choose one that is cost-effective and reliable. Fortunately, there are a number of suppliers that offer high-quality membrane switches at competitive prices.

One such supplier is a company called Switch-Mate. They offer a wide range of membrane switches, from momentary switches to toggle switches to latching switches. They also offer custom designs and are able to provide switches that are waterproof and dustproof, making them ideal for outdoor applications.

Another reliable supplier is a company called MemSwitch. They specialize in custom designs and are able to provide switches that are resistant to extreme temperatures and harsh chemicals. Additionally, they offer competitive prices and fast turnaround times.

Troubleshooting and maintenance for membrane switches is relatively simple. Most problems can be identified by simply examining the switch. Any faulty connections can be easily identified and replaced. Additionally, it is important to make sure that the contacts are clean and free from dust and debris.

When it comes to maintenance, it is important to make sure that the switch is not damaged by the user. This can be done by using an overlay or housing to protect the switch. Additionally, it is important to make sure that the switch is not exposed to extreme temperatures or harsh chemicals.

Membrane switches are a great way to take your product design to the next level. They are durable, reliable, and easy to use, making them ideal for a wide range of products and applications. Additionally, they are cost-effective and can be custom-designed to fit any product design.

When choosing a membrane switch for your product, it is important to consider the type of application it will be used for and the environment in which it will be used. Additionally, it is important to consider the cost and to make sure that the switch is easy to press and that the force required is not too much or too little.

Finally, it is important to choose a supplier that is cost-effective and reliable. There are a number of suppliers that offer high-quality membrane switches at competitive prices. By following these tips, you can ensure that you choose the best membrane switch for your product.

Do you have any questions, or would you like to speak directly with a representative?