The Niceone-Keypad team will understand the customer’s product application direction and budget expenditure, and give the customer the most suitable product draft design. The design and material selection of Medical equipment is very different from those of marine equipment. In order to facilitate the understanding of customers, Niceone-Keypad has made a documentary on the influence of materials and design choices on the product.

Let customers understand the impact of materials and design on the product, customize high value-added (increasing market competitiveness) options, make a suitable customer plan, improve the design drawing, and let the customer confirm, produce, and QC detects the packaging

Membrane Switch

We categorize membrane switches as the user-equipment interface utilities. In other words, these are simply utilities that let’s humans interact with a machine. The user is able to communicate commands to an electric device effectively. Do not confuse them with mechanical switches, as they are composed of copper and plastic parts, in comparison to a substrate and a circuit.

Most membrane switches have a simple, yet effective design. The core functionality of the switch lies in the meeting of electrical contacts on different membranes of the switch. To pass a command, the switch is pressed and the system’s two poles make contact, thus closing the circuit. Once you release the switch, it becomes open, and the connection between poles is terminated.

We firmly believe in designing and delivering the highest quality membrane switches. After all, these switches would elevate the user experience, feel and look of your product.

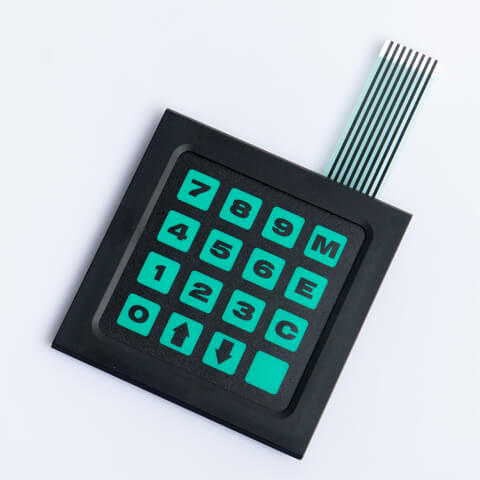

Membrane Keypad

Membrane keypad is the demand of modern electronics as they are excellent keypads for the budget-conscious consumer. In the most basic sense, it features keys that are embedded into a single platform. These keys do not have separate moving parts. As membrane keypads feature pressure pads on which we print the key outlines and the symbols.

The mechanics behind the membrane keypad is very straightforward. There is a conductive metal present at the bottom of the keys. So, when a key is pressed, it results in a circuit creation with the underlying components.

Since there is no denying the importance of a membrane keypad. Therefore, we go the extra mile to ensure the quality and excellence of our membrane keypads. In addition to using premium quality material, we also have the highest-quality testing standard intact to ensure the efficiency, reliability, longevity, and robustness of our membrane keypads.

Membrane Panel

The development of electronic complete machine technology has resulted in the evolution of membrane panel design. One major change is the printing of the panels. In addition to screen printing, we now offer digital printing of the circuit board.

Our membrane panel consists of different layers of polyester printed and assembled together. It lets you create a custom human-machine interface at an extremely reasonable price. The benefits our membrane panel offers:

- Inexpensive control system

- Reduced space requirement

- Customizable Graphic Design

Graphic Overlay

We sometimes refer to a graphic overlay as a nameplate. It is a printed graphic surface that we place on the top of a product’s internal electronics. The graphic overlay serves different purposes. First, it is extremely important for protecting sensitive components and material from wear and tear as well as environmental conditions. Second, it effectively provides a clean instinctive experience for users to interact with any device.

At Nicene, we firmly believe that graphic overlay needs to be of premium quality. It can’t be an afterthought of your design, after all, it is the most frequently used component that your user would come in contact with. Therefore, we always use top-of-the-line material. Our custom overlay feels, looks, and operates to perfection. It is bound to elevate your product’s entire experience.

Design aspects:

What is needed for the panel design of the Membrane Switch?

- The detailed Pantone color number, RAL color number, or Master Color is used as a color reference template to design the color of the overlay.

- Editable vector files. The thickness of the line needs to be greater than 0.1mm before it can be printed.

- Taking into account the use situation: glare, ultraviolet rays, antibacterial, scratch resistance, etc. need to be customized according to the situation. The problem of glare requires the use of frosted ink or frosted materials, and ultraviolet light needs to consider anti-ultraviolet polyester and polycarbonate. Antibacterial This requires consideration of antibacterial materials. For scratch resistance, consider hardened materials.

- Whether there will be problems with color overlay: A common consideration is that multi-color overlay cannot use Screen printing and needs to consider Digital Printing.

- Cost considerations: Digital Printing or Silicone Rubber Keypad can be considered as Overlay when the quantity is large

- Embossing height design: Button height: 0mm-1.3mm. The best height of Tactile Feedback of Button Embossing is 0.3-0.5mm. The height is greater than 0.5mm, and Tactile Dot needs to be added above the Metal Dome to increase the product feel.

The height of the LEDs window: 0-0.5mm. Mainly to prevent LEDs from breaking the Graphic Overlay

Blindspot height: 0.1-0.7mm. Design to reduce operating errors.

- The Embossing shape of the Button is designed with

- Treatment of the back of the window: For OCA windows, a vacuum is needed to eliminate air bubbles between the window and the PC window.

UV dots are printed on the window to eliminate Newton’s rings. It is commonly used for Membrane Switches with a PC window attached to the back of the Overlay and a large gap.

- For the uniform color of the overlay and no other colors, it is recommended to use materials above 0.18, otherwise, there will be bumps

- The choice of thickness: 0.125-1mm, 0.175-0.225 is highly recommended, so that the Tactile Feedback of the product will be better than the other two. If it is Non-Tactile, you can choose 0.125mm or even 0.05mm is feasible, and the cost will be reduced. Metal Dome above 10mm needs to consider shrapnel above 0.225mm, Tactile is better. If it is a backlight solution and Resin Dome structure, you need to choose 0.5-1mm foam tape.

- Exhaust problems and bulging: At this level, you need to consider opening the exhaust holes to ensure the Tactile Feedback of the keys and the resolution of the scheduling problems. The bulge problem is also caused by the inconsistency between the gas inside the button and the outside.

- If the product uses Silicone Rubber Keypad

What are the upgrade designs of Membrane Switch?

1. ESD/RFI/PI: Effectively avoid the static electricity problem of Membrane Switch.

2、Backlight technology: It can make the buttons and logo of Membrane Switch shine.

3、Blind spot embossing: reduce key operation errors.

4、Resin Dome: Make the product more aesthetic performance.

5、Capacitive design: increase product life and reduce product unit price.

6、Plug-in type: reduce mold cost.

7、Silicone Rubber Keypad surround type: Waterproof performance is greatly improved

8、OCA: The bonding of the PC window and the panel without air bubbles is different from the regular panel printing dots.

9、Brushed metal design: more modern aesthetics

10、Fit to various backplanes: reduce customer assembly time and increase product thickness

11、Digital Printing: Let your products have gradient colors.

12、Metallic panel design: use mirror silver or brushed material.

13、Combination with touch screen: The combination of OCA and touch screen often appears in Membrane.

More design improvements can be negotiated with Niceone-Keypad to make your Membrane Switch more competitive

Prepare a suitable customer’s plan and perfect the design drawing for the customer to confirm:

After the customer understands its needs, the choice of product materials, whether to choose a high value-added design, and cost estimation, we can design the drawings. The time for designing drawings is generally 1-7 days according to the completeness of the drawings. The best customer drawing is to show three contents to Niceone-Keypad designer:

1、Editable vector graphics

2、Accurate color-coding or customer sample color card.

3、Complete circuit principle and corresponding panel buttons, PIN1 position, outlet, and corresponding positioning size.

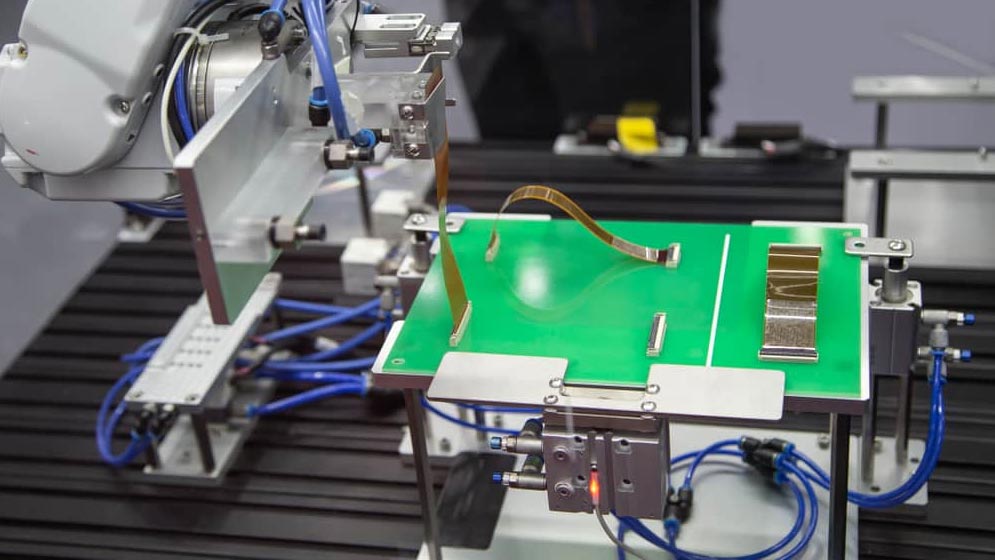

Production of Membrane Switch:

1) Installation and adjustment of squeegee and squeegee 2) Check screen and registration 3) Take ink 4) Trial printing 5) Check film and pattern, check whether it meets special requirements 6) Printing production 7) Baking ink 8 ) Recycling ink 9) Cleaning knives and screens

Convex process: After heating the Overlay, it is embossed.

Placement process:

Welding resistance and LED lights: Welding resistance and LED lights on the front of the FPC circuit that has been checked by PQC, and the circuit is out after completion

Adhesive: Align the four-corner frame line on the back of the FPC line that has been punched out, and paste the cut adhesive.

Placement sheet: align the four-corner frame line on the front of the FPC line with adhesive backing

Paste the cut interstitial piece, and place the fixed layer of shrapnel after finishing

Swing shrapnel

Paste the fixed layer: place the shrapnel in the pasted gap hole and paste the cut solid

Fixed layer and fixed shrapnel, after finishing punching line synthetic punching

Attach waterproof frame: align the four corners on the front of the FPC line with the fixed layer

Attach the cut waterproof frame to the frame line, and attach the light guide plate after completion

Pasting light guide plate and diffusion film: fill in the light guide in the waterproof frame that has been pasted

Plate and diffusion film, complete the backline bonding

Face line fitting: center the punched and punched panel and the line to fit the line, and then punch the face line into the shape after completion

How to ensure that your Membrane Switch is guaranteed of high quality-Membrane Switch detection

Silkscreen part:

Niceone-Keypad also needs to do (the silver oil line is also tested in strict accordance with the following requirements):

1 Check the film and template of the printed pattern; 2 Check whether the color meets the requirements of the model or color number; 3 The printed text and pattern must be clear, and there must be no blur, ghost, or jagged; 4 Pay attention to the blocking of the net, foreign matter, oil, and scraper during the printing process Marks, sticky nets, inaccurate positioning, etc.; 5 Ink adhesion inspection.

Stamping part:

1、When drilling the pipe position hole, pay attention to the center position of the pipe position hole, and don’t make a deviation;

2、Check the embossed product against the sample plate for deviation, and do related tests;

3、Check whether the pipe position hole is offset.

4、Check whether the convex position of the product after hot pressing and convex deviates, indentation, etc.;

Fitting part:

1 Correctly attach the adhesive tape according to the template and process;

2 Pay attention to air bubbles, dust, foreign matter, and deviation when attaching adhesive tape;

3 Pay attention to cooperating with the procedures of other departments during the entire lamination process.

4Whether the correct adhesive tape is attached;

5 Check for problems such as bubbles, dust, foreign matter, and deviation after bonding.

Appearance inspection part:

5、Pay attention to the inspection panel not to have black spots, nail marks, oil stains, white spots, indentations, etc.;

6、Check whether the pasting glue is well and correctly pasted

7、If there is oil on the panel, be careful not to have oil, dust and other sundries on the surface;

8、If there is a panel that is manually stamped, hot pressed, and convex, check whether the convex position is offset, etc.;

9、Packaging inspectors should pay attention to the inspection while not scratching the panel with their fingers.

Line function part:

According to the actual drawings, it mainly detects resistance, electrical function, circuit principle, and short circuit and open circuit problems.

Extended part

Overlay:

The Overlay of Membrane Switch needs to be tested four 4 times: A. Before printing, it is necessary to check whether the panel material is selected according to the production documents, and perform a 100-grid test to check the ink adhesion. B. After printing, you need to check again whether the color number of the color meets the requirements of the drawing, and whether there is trachoma and light transmission. C. It is necessary to check whether the ink is peeled and scratched when embossing. D. Check whether the Overlay is scratched after placement.

Tactile Feedback:

10、Tactile Feedback test: Tactile Feedback test needs to pay attention to the height of the button and select the appropriate metal load and stroke. The selection of molds, the selection of structures, and the venting holes all need to be evaluated before the project is made when drawings are made to avoid all kinds of problems. QC testing also needs to pay attention to the Tactile Feedback test, unless it is a Non-Tactile Membrane switch without any hand feeling.

11、Membrane Switch circuit function test: Whether the resistance is too large, whether the electrical function is realized, and short circuit and open circuit problems need to be tested.

Backlit solution:

12、Whether the light source is evenly illuminated on the part that needs to be lit

Resin Dome:

13、Resin buttons are free of any impurities.

Problems and solutions that will occur in Membrane Switch:

14、Does the color need to be gradual and too many colors: Digital Printing

15、Whether the Membrane Switch is used in a high-voltage electrostatic environment (silver migration): 1. PI, RFI, ESD, etc. as the fixed layer 2. Select Flex Copper Circuit and Printing Circuit Board as the circuit.

16、Use and storage environment: The main impact is that the use and storage environment of Membrane Switch made by Adhesive, 3M adhesive can reach -25-80 degrees Celsius, while DT and Nitto adhesive tapes are usually 10-80 degrees Celsius and cannot be used at low temperatures.

17、Membrane Switch appears Newton’s ring: use OCA technology or UV dots printed between the PC window and the Overlay.

18、Scratches appear in the Membrane Switch window: Use hardened polycarbonate material for the panel or window, or use EBGmaterial as Overlay.

19、The resistance of the Membrane Switch is too high: the line is too long, and the Metal Dome needs to be plated with NI or GOLD. The best solution is to use Flex Copper Circuit or Printing Circuit Board.

20、The tactile feedback of the Membrane Switch is poor: Metal Dome needs to choose the appropriate load, and the thickness of the Overlay material needs to be 0.125-0.2mm and it needs to be convex. The adhesive of 0.3mm or less should be selected for the surface adhesive layer.

21、Membrane Switch function short circuit: Whether the silver oil circuit is fuzzy or short-circuited. Metal Dome is off.

22、The lead wire of the Membrane Switch should be scratched by electronic components, causing the circuit to be short-circuited: the circuit can choose to mount Mylar to solve the problem. Choose Flex copper circuit.

23、Metal Dome offset of Membrane Switch: Metal Dome fixture is required for the factory mounting process.

The packaging of Niceone-Keypad:

24、The threaded end can use a paper label or pad printing label to add product PN, PO, and Date.

25、The label of the outer box allows customers to understand the quantity and date of each box and can trace the product.

54. The use of foam reduces product collisions.